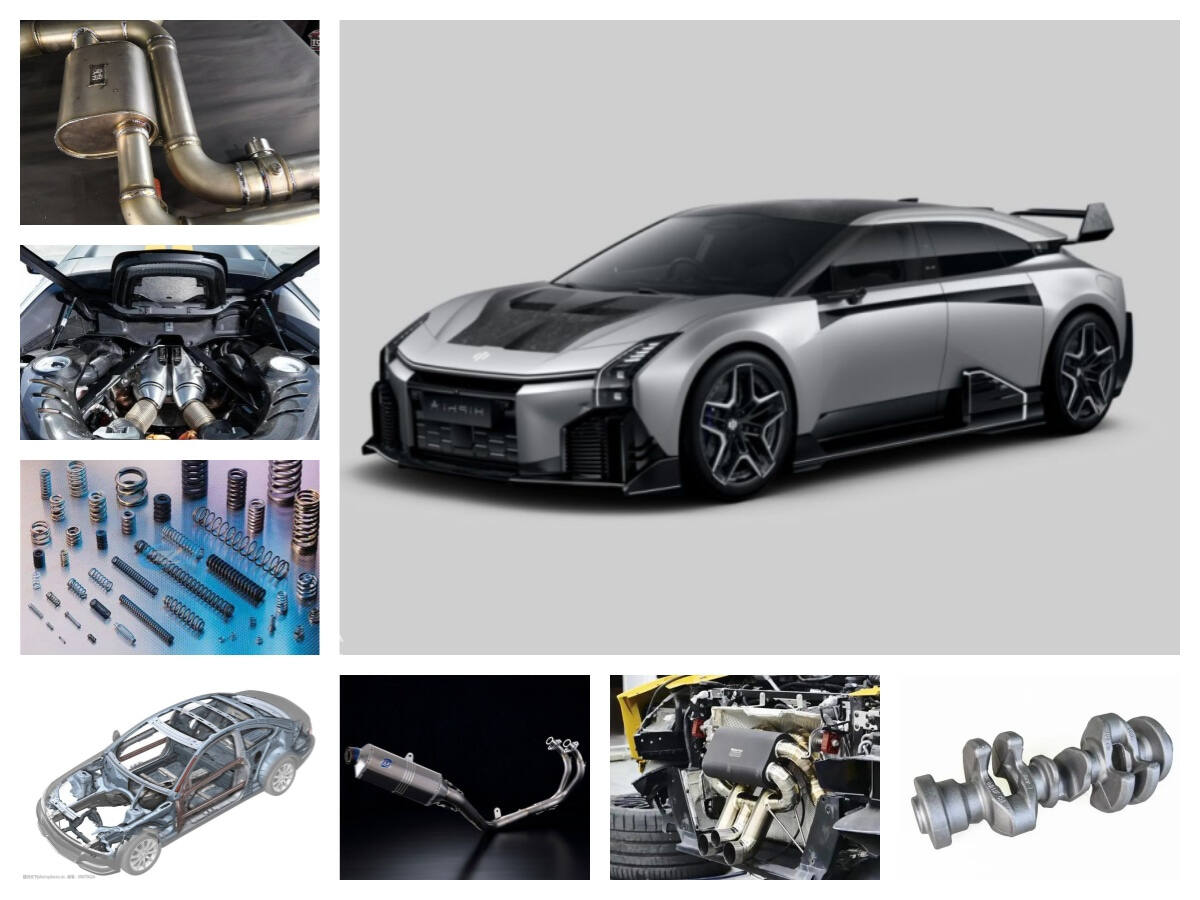

Titanium alloy plays an important role in automobile manufacturing due to its high specific strength, which enhances the performance and economy of automobiles.

(1)Valve: Titanium alloy valves are widely used in automobile engines because of its light weight and high strength characteristics. For example, the United States commonly uses Ti-6Al-4V alloy to manufacture intake valves and Ti-6Al-2Sn-4Zr-2Mo alloy to manufacture exhaust valves. Toyota Corporation in Japan uses Ti-6Al-4V/TiB alloy to prepare intake valves and Ti Al Zr Sn Mo Nb Si/TiB alloy to prepare exhaust valves.

(2) Connecting rod: Titanium alloy connecting rod can effectively reduce the weight of the engine and improve the performance of the car. For example, Japan's Honda Motor Company used forged titanium connecting rods in the NSX racing V-6 engine.

(3) Crankshaft: Although the current application of titanium alloy in crankshaft is relatively small, but Japan specially developed the Ti-3Al-2.5V alloy, which has been verified in the Honda racing car, shows titanium alloy can effectively reduce the quality and improve engine speed. Exhaust system: The application of titanium alloy in the exhaust system is mainly reflected in its light weight and corrosion resistance. For example, the titanium return pipe used in the new Chevrolet Corvette Z206 car avoids pitting and weld corrosion problems that occur on stainless steel pipes, while also improving fuel combustion efficiency and acceleration. Japan's Honda and four other companies have also adopted titanium-made silencers for large cars and individual medium-sized cars.

Vibration damping system: Titanium alloy springs have the characteristics of light weight, good corrosion resistance and low shear modulus. For example, Germany’s Volkswagen already used Lupo FSI titanium alloy gear springs in some cars. Titanium alloy springs reduce weight by more than 60% compared with steel springs, can effectively improving the resonance frequency and service life of springs.

Vehicle body frame: Titanium alloys are used to manufacture vehicle body frames due to their high strength and low-density properties. For example, Japanese automakers use pure titanium welded tubes to make frames, which can provide adequate security. The titanium alloy body frame not only has high strength and good toughness, but also has excellent corrosion resistance.

Fasteners: Titanium alloy bolts and fasteners are used to replace traditional steel bolts and fasteners due to their lightweight and high-strength properties. For example, Ti-6Al-4V automotive fasteners produced by powder metallurgy technology can effectively reduce weight.

(1)Turbocharger: The turbocharger rotor made of titanium alloy can work in the high-temperature exhaust gas above 850 °C for a long time without significant performance degradation.

(2)Valve seat: Titanium alloy valve seat has been widely used in racing and sports cars, mainly prepared by Ti-6Al-4V or Ti-5Al-2Cr-1Fe alloy.