Due to the excellent corrosion resistance characteristics of titanium alloy, it is widely used in the petrochemical field.

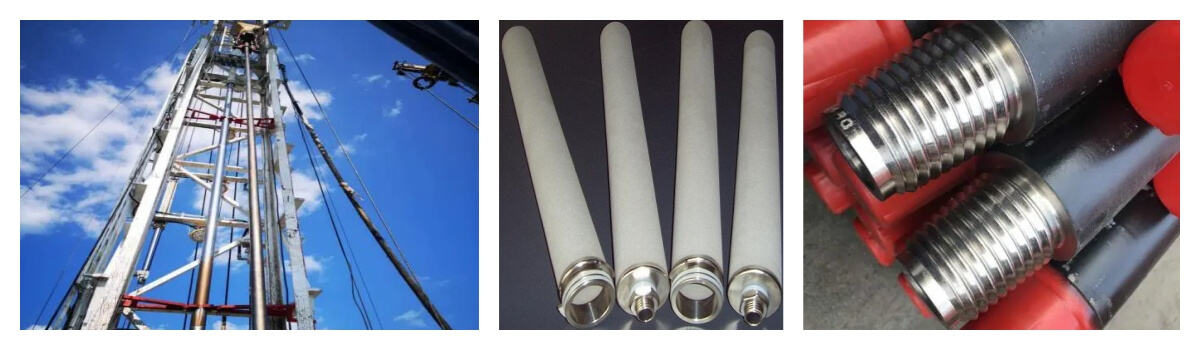

Offshore oil platforms: Offshore oil exploration platforms need to withstand seawater corrosion and stress corrosion for a long time. Titanium alloys are widely used in oil platform pillars, rope supports, high-pressure pumps, lifting pipes, couplings and other parts because of their excellent corrosion resistance. Titanium alloy has higher specific strength, wider operating temperature range, larger elastic deformation ability, lower coefficient of expansion, non-magnetic properties, and easier processability, making it very popular in petroleum equipment. It is suitable for manufacturing drilling rods, drill collars, pumps, valves, heat exchangers, pipelines and other equipment, can meet the normal use requirements of various detection, communication and control means. For example, the North Sea oil drilling platform in the United States uses 100 titanium heat exchangers; The Heidurum project in Norway used the world's first titanium high-pressure vertical shaft.

Petroleum drilling and production equipment: Titanium alloys perform well in oil and gas drilling, especially in highly corrosive environments. For example, the UK used titanium drilling and production equipment at a depth of 600m temperature262°C and containing 5% H2S and 25% NaCl condition. The former Soviet Union also used titanium pumps, titanium valves, and titanium rinsing brine equipment. In China, in order to solve the corrosion problem under high temperature and high pressure in natural gas wellheads, Ti-6Al-4V valve plates, valve seats and valve stems are used.

Drill pipe: Due to titanium alloy have characteristic of high strength, low density, good seismic resistance and corrosion resistance, it is performing well in high-temperature, hydrogen sulfide, acidic and highly corrosive conditions, especially for complex well conditions like ultra-deep wells and short-radius. The laboratory has confirmed that under cyclic stress of 30,000psi-40,000psi, the fatigue life of titanium is 10 times that of ordinary steel. The specific strength of titanium alloy drill rods is 3.5 times that of stainless steel, 1.3 times that of aluminum alloy, and 1.6 times that of magnesium alloy. Titanium alloy’s high strength and low-density features make it more safety and durability, suitable for drilling operations in complex well conditions, such as ultra-deep wells and short-radius wells.

Chemical equipment: Titanium alloy is widely used in chemical production in distillation towers, reactors, pressure vessels, heat exchangers, filters and measuring instrument’s pumps, valves, pipelines and other equipment due to its excellent corrosion resistance. Especially in the crude oil refining process, when there is high sulfur and high salt content, use titanium equipment is very suitable. Titanium and titanium alloy materials have been successfully used in atmospheric distillation units, condensers, and other applications abroad.

Chemical Equipment: Titanium alloy is particularly important in the chlor-alkali industry and is used in the manufacture of metal anode electroliers, ion membrane electrolyzers, wet chlorine coolers, refined brine preheaters, dechlorination towers, chlorine-cooled scrubbers, etc. In the production process of soda ash, using titanium pipes instead of cast iron pipes significantly improves the corrosion resistance and service life of the equipment, the service life is expected to be more than 20 years, with significant economic benefits. In the purification process of coke oven gas, since the gas contains highly corrosive H2S, NH3, and HCN, the equipment is severely corroded. Therefore, titanium materials are used for the main equipment in foreign countries.

Seawater Desalination Equipment: Titanium alloys are also used in seawater desalination equipment, especially in heat transfer tubes and condensers. Due to its corrosion resistance and lightweight characteristics, Titanium tubes have gradually replaced the original copper alloy tubes.