Baotai road,weibin zone,baoji city, Shaanxi Province,China +86-15399417429 [email protected]

Ylasting Titanium factory has ten years of experience in titanium materials, providing one-stop titanium product supply for domestic and foreign trading companies. After continuous improvement and modification, it now has a complete production line, can offer many titanium products, such as different grade and technical standard titanium plate, titanium bar, titanium foil and titanium wire.A lot of stock and can ship out within 2days.

Ylasting have more than 5+PhD in Materials. All raw materials are qualified by third party inspection,Each processing process has strict indicators and testing.

Global Countries

Customer Visit

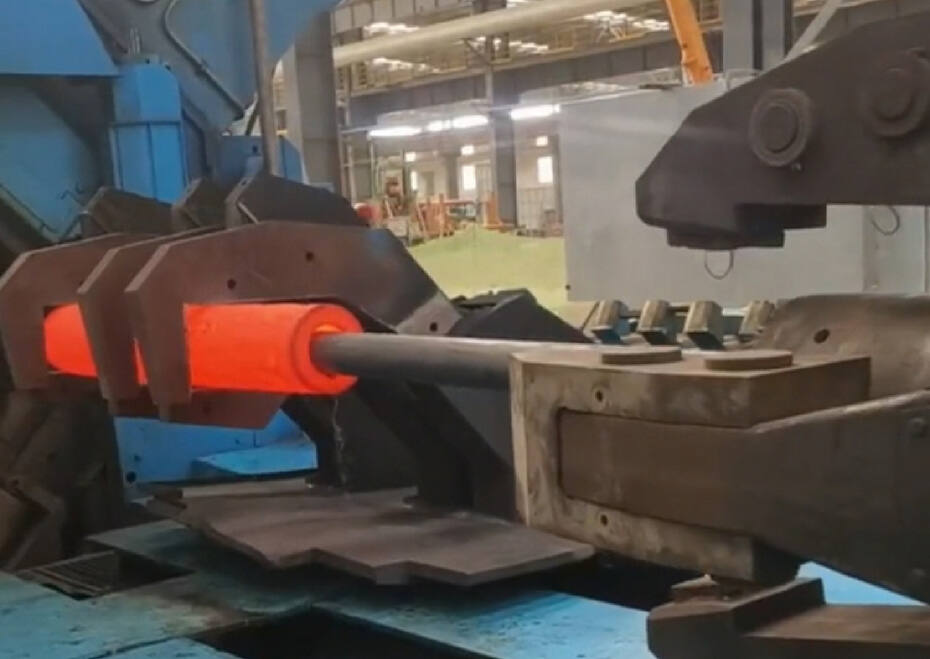

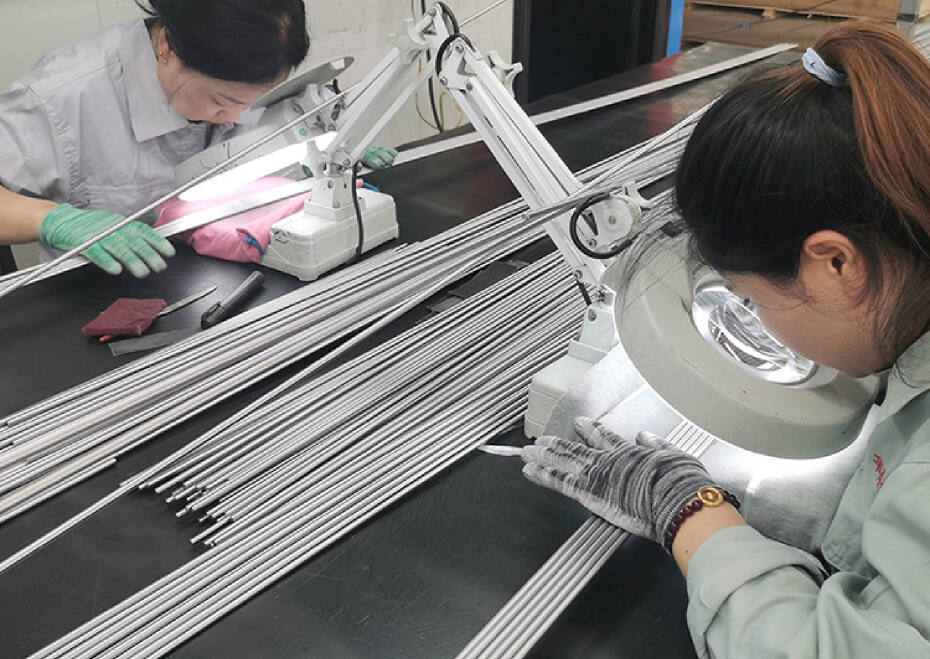

Production Equipment

Bad Quality

500

Sets of Products

Ylasting titanium factory have nearly 40+ production equipments , such as 4500T press,Plate cold rolling mill,Straightening machine,Four-linkage high-precision grinder,Roller hearth annealing furnace ,Reversible wet sander,Vacuum consumable electric arc furnace, Water cutting machine and so on,Can help you provide one-stop material solution and One-stop production custom.

At Ylasting titanium, titanium plate and sheet is one of the popular products for customers,our standard size is 2000mm length and 1000mm width, so if you have small size or big size all we can offer for you, if small size we can cut for you, if big size we can produce for you.

Ylasting Titanium Industry has ten years of experience in titanium materials, providing one-stop titanium product supply for domestic and foreign trading companies. The quality has been unanimously recognized.

Ylasting titanium factory as China titanium material production base,Our products have been recognized and highly praised by many overseas customers. After more than ten years of continuous development, we have obtained the certifications for titanium materials in various fields.

The international standard basis of the quality management system

The CE mark indicates that a product meets European Union safety, health, and environmental protection standards

Special requirements in the aerospace field: Special requirements in the aerospace field

Medical Device Quality Management System

Supplier of sponge titanium:The largest raw material suppliers in China: Baoti, Zunyi Titanium Industry

Incoming inspection:Before entering the warehouse, we conduct inspection items for each batch of sponge titanium: chemical composition analysis (to ensure compliance with standards such as ASTM B299 and AMS 4951), appearance inspection, particle size/density (affecting smelting), impurity control (especially key elements such as O, N, H, Fe, and C), and verification of the quality guarantee certificate provided by the supplier.

Traceability:Each batch of raw materials is marked to ensure the correlation between subsequent production batches and conduct a secondary inspection.

We will cover the smelting process, process parameter monitoring (real-time monitoring and recording of key parameters such as smelting current, voltage, vacuum degree, and cooling rate), process inspection: first ingot/batch analysis (chemical composition recheck), ingot surface inspection (cracks, cold shuts, etc.), uniformity assessment, and regular maintenance and calibration records of equipment.

During the processing and forming process(forging / rolling / extrusion / stretching, etc.) control is carried out through the process regulations, key parameters (temperature, deformation amount/deformation rate and heat treatment), and process inspection.

During the surface treatment and finishing process, the following key points are strictly controlled. Control of acid washing/alkali washing solution concentration, temperature and time; sandblasting/polishing: control of sand particle size, pressure and uniformity; cleaning and drying: cleanliness control to prevent contamination and hydrogen embrittlement risks.

We will complete the following key items of testing through internal laboratory testing and third-party testing: chemical composition analysis, mechanical property testing, metallographic analysis, non-destructive testing, dimensional and positional tolerance testing, surface quality inspection, etc. Finally, a standardized and detailed test report is obtained.

Copyright © 2026 Xi'an Ylasting Titanium Industry Co.,Ltd. All rights reserved. — Privacy Policy