Titanium was discovered by English mineralogist and mineralogist William Gregor in 1791. Gregor analyzed magnetic ores sands in Cornwall, England, and isolated ilmenite.

Four years later, in 1795, from rutile produced by Hungary, German chemist Martin Heinri Klaproth isolated titanium oxide, and named this new element Titanium.

Metallic titanium was first prepared in 1910 by Matthew A. Hunter at Rensselaer Polytechnic Institute by heating TiCl4 with sodium。

In 1932, Luxembourg chemist Wilhelm Justin Kroll used TiCl4 and Na to produce a large amount of titanium. At the beginning of World War II, he proved in the U.S. Bureau of Mines that titanium could be commercially extracted by using Ca instead of Mg as a reductant to reduce TiCl4, the method is known as the “Kroll process”, and is still widely used until today. Titanium metal was first commercially produced by DuPont in the United States in 1948.

Up to now, China, the United States, Russia, and Japan are the main producers of titanium products, their combined output accounts for over 90% of global titanium production. 1.Basic characteristics of titanium and it’s alloys

To be honest, Titanium is not a rare metal, it is the ninth-most abundant element in Earth's crust, and the fourth-most abundant structural metals, only after aluminum, iron and magnesium. But it is a pity that ores with high titanium content are rarely found in the earth's crust, and pure titanium has never been discovered. Since it is very difficult to produce pure titanium metal, the Titanium is always so “expensive”. Even now, titanium can only be produced in batches and intermittently, don’t have continuous production process like other structural metals.

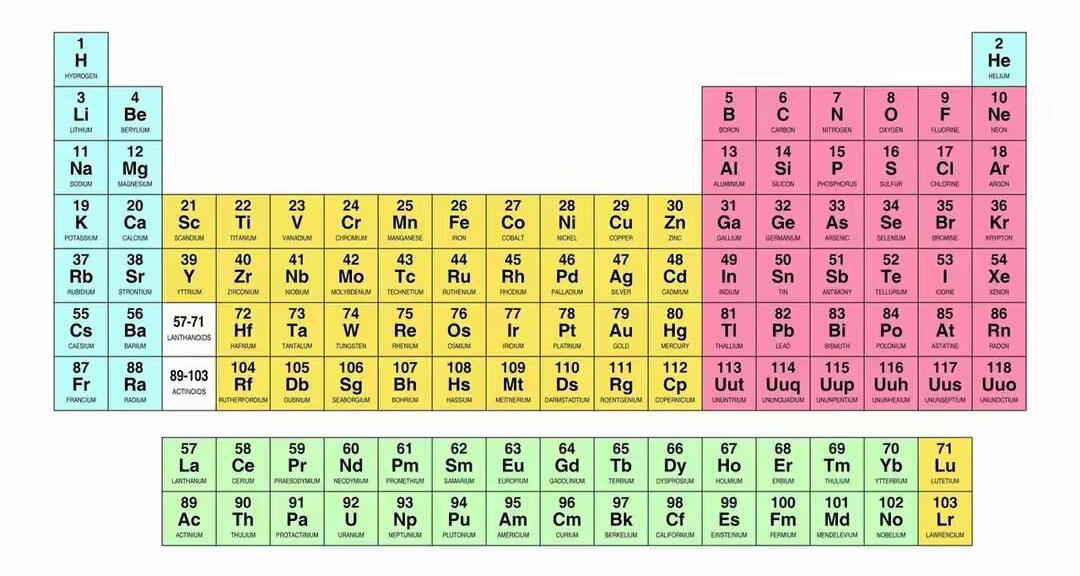

Among the 112 known chemical elements in the periodic table (Figure 1), about 85% are metals or metalloids. There are various ways of classifying metals, such as ferrous metals and non-ferrous metal, light metals and heavy metals. Titanium is non-ferrous metal and light metal.

Titanium's atomic number is 22. Its Standard atomic weight is 47.90, the density is 4.5g/cm³, and the melting point is up to 1725℃. Titanium is a dimorphic allotrope, at temperatures below 882.5℃, it is a close-packed hexagonal structure α-titanium, and above 882.5℃, it will into a body-centered cubic structure β- titanium.

The properties of metals mainly depend on the metallic bonds between atoms in the lattice, which means that the freely movable valence electrons in the lattice lead to its typical metallic properties, such as electrical conductivity, which can be alloyed by plastic deformations resulting from the atomic slip in the lattice as well as by doping impurity atoms to the lattice. Adding other metal elements to pure titanium to improve its room temperature (high temperature) mechanical properties and corrosion resistance, is called titanium alloy.

Titanium and titanium alloys have two outstanding properties: high specific strength and excellent corrosion resistance.

Specific Strength is an indicator that measures the relationship between the strength and density of a material. It is defined as the ratio of a material's strength (usually expressed as tensile strength) to its density. Specific strength is used to assess the load-bearing capacity of materials under unit mass and is an important parameter in designing lightweight and high-strength structures. Titanium alloys are recognized for its lightweight and high-Specific Strength, which makes them particularly popular in the aerospace industry.

Corrosion resistance refers to the ability of a material to resist chemical or electrochemical reactions, these reactions may cause degradation, damage or deterioration of the material. Corrosion resistance is a very important property in materials science, especially for applications that require exposure to harsh environments or corrosive media. The corrosion resistance of titanium alloy is mainly due to it can form a dense, self-healing oxide thin film formed on its surface. This passivation film gives titanium alloys 100 times higher corrosion resistance than stainless steel. In ocean engineering, titanium alloy is known as the "ocean metal" and has gradually replaced stainless steel due to its lightweight, high strength, and corrosion resistance characteristics.

Hot News

Hot News