What is ASTM B265 Titanium Plate?

The designation "ASTM B265" refers to a standard specification established by ASTM International (American Society for Testing and Materials). It is not a single product grade, but rather the benchmark that governs the manufacturing, chemical composition, mechanical properties, and tolerances of a wide range of titanium plates. When you procure an ASTM B265 Titanium Plate, you are acquiring a product with certified quality and traceability, ensuring it adheres to the specific requirements for grades such as Grade 2 (Commercially Pure), Grade 5 (Ti-6Al-4V), and others. This standard is essential for ensuring material consistency and reliability in high-specification industries like aerospace, chemical processing, and medical manufacturing.

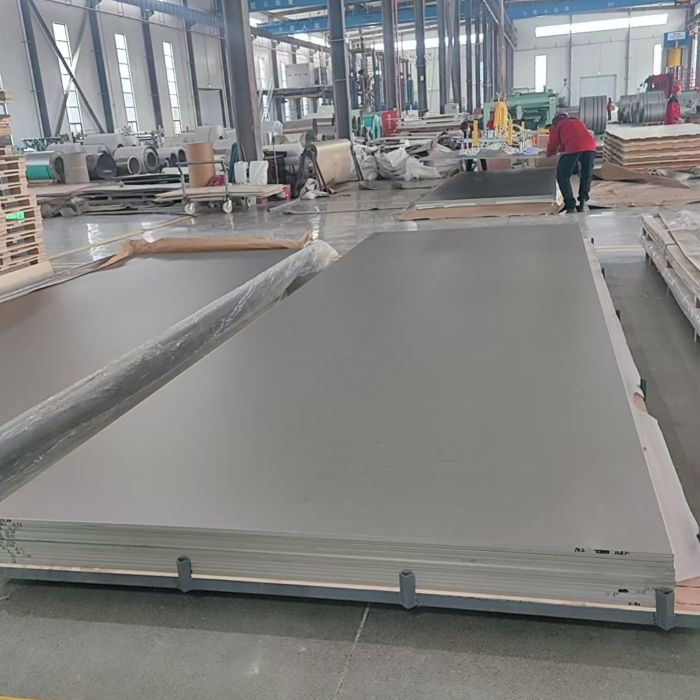

| Name |

Titanium sheet |

| Classification |

Pure titanium/Titanium alloy |

| Standard |

GB/T3622-199,ASME SB265,ASTM B265,AMS4911,AMS4907 |

| Grade |

TA1-TA4,GR1-GR5,GR7,GR9,GR11,GR12 |

| Size |

Thickness(1-5mm)*Width(≤1000mm)*Length(≤4000mm) |

| Thickness(5-30mm)*Width(≤2000mm)*Length(≤6000mm) |

| Thickness(30-100mm)*Width(≤3000mm)*Length(≤4000mm) |

| Processing method |

Hot rolling/Cold rolling |

| Test |

UItrasonic testing,X-ray testing |

Applications:

The reliability and superior properties of our ASTM B265 Titanium Plate make it essential for numerous industries:

· Aerospace & Defense: Used for airframe structures, engine components, firewalls, and spacecraft parts where strength, low weight, and temperature resistance are crucial.

· Chemical Processing: Ideal for manufacturing pressure vessels, heat exchangers, tanks, and piping systems due to its immunity to corrosion from many chemical agents.

· Marine Industry: Extensively used in shipbuilding, offshore oil rigs, and desalination plants because of its complete resistance to saltwater corrosion.

· Medical Field: The preferred material for orthopedic implants (hip, knee), dental implants, and surgical devices.

· Power Generation: Employed in steam turbine condensers and other heat transfer equipment where corrosion resistance and efficiency are paramount.

We are committed to providing our customers with the highest quality titanium products, backed by unparalleled expertise and service. When you partner with us, you benefit from: · Guaranteed Quality: Our plates are sourced from premium-grade titanium sponge and are subject to rigorous quality control measures, including 100% ultrasonic testing to ensure they are free from defects.

· Compliance with International Standards: We manufacture and supply CP Titanium Plate ASTM B265 in strict adherence to ASTM, ASME, and other international standards, providing you with material you can trust.

· Full Traceability: Each plate comes with a Material Test Certificate (MTC), ensuring complete traceability from raw material to the final product.

· Customization and Flexibility: We offer a wide range of sizes and grades and can provide custom-cut plates to your exact specifications, minimizing waste and reducing your processing time.

· Expert Support: Our team of material specialists is dedicated to helping you select the right grade and specification for your application, ensuring optimal performance and cost-effectiveness.