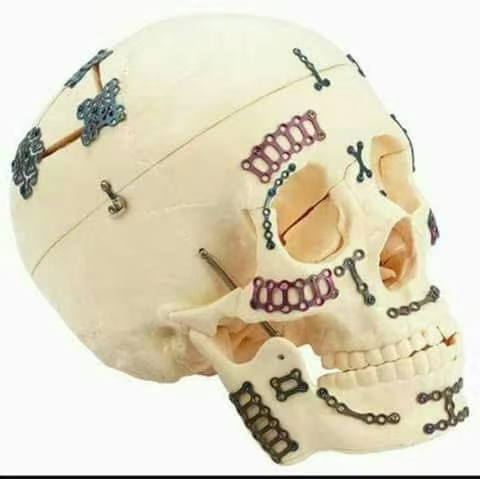

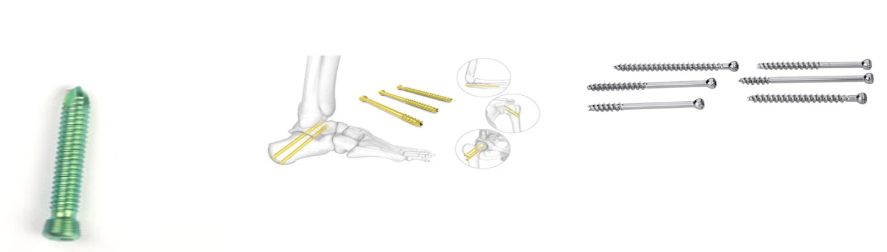

Medical implant titanium rod is a surgical implant made of titanium or titanium alloys, primarily used to stabilize and support bones during the healing process. These titanium rods are commonly used in orthopedic surgery, especially to treat fractures, spinal injuries and bone deformities.

High Strength

Medical implant titanium rod offers a tensile strength of up to 950 MPa. Compared to stainless steel of the same size and weight, it can handle a much greater load. Its strength, combined with its low weight, helps reduce strain on the body while keeping the structure stable.

Precision Processing

The Medical GR23 GR5 ELI Titanium Rod is made with 5-axis CNC machining to ensure high accuracy. The surface roughness is Ra ≤ 0.8 μm, and porosity stays below 0.5%, allowing more than 95% contact with bone. We also offer custom 3D shaping, with bending accuracy controlled within ±3°, making it easier to match complex anatomical needs.

Lightweight Design

Titanium alloy weighs just 4.5 g/cm³ - about 40% less than standard implant metals. A single spinal rod weighs between 12 and 18 grams. This lighter design helps reduce energy use during movement by 17%, which is especially useful for multi-level implants and can greatly improve post-op mobility.

Specifications:

Product name |

Medical implant titanium rod |

Material grade |

GR3 GR5 ELI GR23 TI6AL4V ELI TC4 ELI |

Standard |

ASTM F67 ASTM F136 GB 13810 |

MOQ |

1KG/PCS |

Status |

Annealed state (M), hot working state (R), cold working state (Y) (annealed, ultrasonic flaw detection) |

Tolerance |

H11 H9 H7 H6 |

Production method: |

Forging and hot rolling |

Testing methods |

According to customer requirements, radiographic testing, coloring, flaw detection tests and other tests can be conducted. |

Application |

Surgical instruments and also into accessories for the body of a vegetative person. |

We will complete the following key items of testing through internal laboratory testing and third-party testing: chemical composition analysis, mechanical property testing, metallographic analysis, non-destructive testing, dimensional and positional tolerance testing, surface quality inspection, etc. Finally, a standardized and detailed test report is obtained.

| QUALITYCERTIFICATE OF TITANIUM PRODUCT |

| Contract No. |

Commodity |

Designatio

n

|

Lot No. |

Heat No. |

Condition |

Size(mm) |

Quantity(pc) |

Net weight |

Specification |

| 一 |

Titanium Bar |

Ti6Al4vELI |

2350745 |

5341ELI-21230030 |

M |

φ2.0*2000 |

/ |

/ |

ASTMF136 |

| Tensile Test |

Sample Condition |

Tensile

Strength

Rm/[MPa]

|

Yield Strength

Rp0.2/[MPa]

|

Elongation

A/[%]

|

Reduction of area

Z/[%

|

a

[J/cm²]

|

HB(d)

[mm]

|

a/°

Bend Test

|

| M |

LI |

1005 |

839 |

25.5 |

一 |

一 |

一 |

一 |

| L2 |

1007 |

841 |

26.0 |

一 |

一 |

一 |

一 |

| Standard |

≥860 |

≥795 |

≥10 |

一 |

|

|

|

| Others |

Dimensional

Inspection

|

Visual

Inspection

|

Microstructure |

Macrostructure |

Ultrasonic

Inspection

|

Surface

Contaminati

on Test

|

Phase Transition

Point(℃)

|

Melting Method |

| ok |

ok |

ok |

ok |

一 |

ok |

一 |

|

| Chemical Composition(%) |

| Location |

Ti |

一 |

Al |

V |

Fe |

C |

N |

H |

0 |

(others) |

| Top |

Remainder |

一 |

6.17 |

4.09 |

0.158 |

0.011 |

0.008 |

0.0031 |

0.110 |

(each)<0.10 |

| Middle |

Remainder |

一 |

|

|

|

|

|

|

(total)<0.40 |

| Bottom |

Remainder |

一 |

6.22 |

4.13 |

0.165 |

0.010 |

0.009 |

0.114 |

|

| Standard |

|

|

5.5~6.5 |

3.5~4.5 |

≤0.25 |

≤0.08 |

≤0.05 |

≤0.012 |

≤0.13 |

|

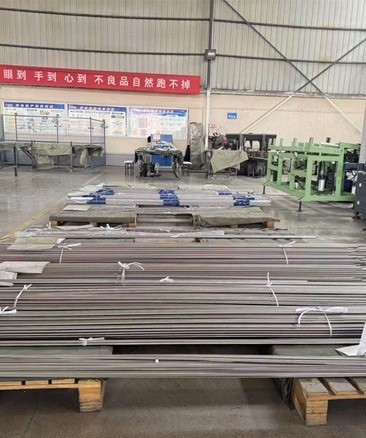

Ylasting titanium factory has 16 lines for medical titanium round rod production, titanium bar main production line as below.

Medical Titanium Round Bar production line

Ylasting titanium factory can produce any size and any grade medical titanium round bar and rod , all have stock,can ship out within 2days.

Medical titanium round bar is considered the most attractive metal materials for biomedical applications. Ti-6Al-4V has long been favored for biomedical applications. However, for permanent implant applications, the alloy may have toxic effects due to released vanadium and aluminum. Therefore, vanadium-free and aluminum-free alloys have been introduced for implant applications.

Due to Titanium alloys have excellent biocompatibility, corrosion resistance, and moderate strength features.They are widely used in orthopedic implants, such as artificial joints, fracture fixation instruments, spinal correction equipment, etc.

Because titanium alloys have excellent compatibility with the human body and are non-toxic and harmless to it, they are used in bone joints.

Titanium alloy is used in dentistry for dental implants, crowns, bridges and inlays. Since the elastic modulus of titanium alloys is similar to that of natural teeth, dental implants made of titanium alloy can reduce the pressure on alveolar bone, improve stability and success rate of implants.

Because titanium alloys have excellent compatibility with the human body and are non-toxic and harmless to it, they are used in bone joints