As a seasoned titanium bar supplier, I understand the critical importance of ensuring the purity of titanium bars. Titanium is a remarkable metal known for its high strength, low density, and excellent corrosion resistance, making it a sought-after material in various industries, including aerospace, medical, and automotive. However, the performance and reliability of titanium bars largely depend on their purity. In this blog, I will share some key strategies and practices to ensure the purity of titanium bars.

Raw Material Selection

The journey to producing pure titanium bars begins with the careful selection of raw materials. Titanium is typically extracted from titanium ores, such as ilmenite and rutile. The quality of these ores can vary significantly, and it is essential to source them from reliable suppliers. High-quality ores with low levels of impurities are preferred as they serve as a solid foundation for the production of pure titanium bars.

When evaluating potential ore suppliers, we conduct thorough due diligence. We assess their mining practices, quality control measures, and reputation in the industry. We also request detailed chemical analysis reports to verify the composition of the ores. By choosing high-quality raw materials, we can minimize the presence of impurities in the final titanium bars.

Melting and Refining Processes

Once the raw materials are selected, the next step is the melting and refining processes. These processes are crucial for removing impurities and achieving the desired level of purity. There are several methods for melting and refining titanium, including the Kroll process and the Hunter process.

The Kroll process is the most widely used method for producing titanium sponge, which is then melted to form titanium bars. In this process, titanium ore is first converted into titanium tetrachloride, which is then reduced with magnesium to produce titanium sponge. The sponge is then melted in a vacuum arc remelting (VAR) furnace to remove any remaining impurities and to ensure a homogeneous composition.

The Hunter process, on the other hand, involves the direct reduction of titanium ore with sodium to produce titanium sponge. This process is less commonly used but can be more cost-effective in certain situations.

Regardless of the method used, strict quality control measures are implemented during the melting and refining processes. We monitor the temperature, pressure, and chemical composition of the melt to ensure that the purity requirements are met. We also conduct regular sampling and analysis to verify the quality of the titanium bars.

Quality Control and Testing

Quality control and testing are essential steps in ensuring the purity of titanium bars. Throughout the production process, we conduct a series of tests to monitor the quality of the bars and to detect any potential issues. These tests include chemical analysis, mechanical testing, and non-destructive testing.

Chemical analysis is used to determine the composition of the titanium bars and to identify the presence of any impurities. We use advanced analytical techniques, such as inductively coupled plasma mass spectrometry (ICP-MS) and optical emission spectrometry (OES), to accurately measure the concentration of various elements in the bars.

Mechanical testing is used to evaluate the mechanical properties of the titanium bars, such as strength, ductility, and hardness. We conduct tests, such as tensile testing, compression testing, and hardness testing, to ensure that the bars meet the required specifications.

Non-destructive testing is used to detect any internal defects or flaws in the titanium bars without damaging them. We use techniques, such as ultrasonic testing, radiographic testing, and magnetic particle testing, to identify any potential issues that could affect the performance of the bars.

By conducting comprehensive quality control and testing, we can ensure that the titanium bars we supply meet the highest standards of purity and quality.

Storage and Handling

Proper storage and handling are also important factors in maintaining the purity of titanium bars. Titanium is a reactive metal that can easily react with oxygen, nitrogen, and other elements in the environment, which can lead to the formation of oxides and nitrides and reduce the purity of the bars.

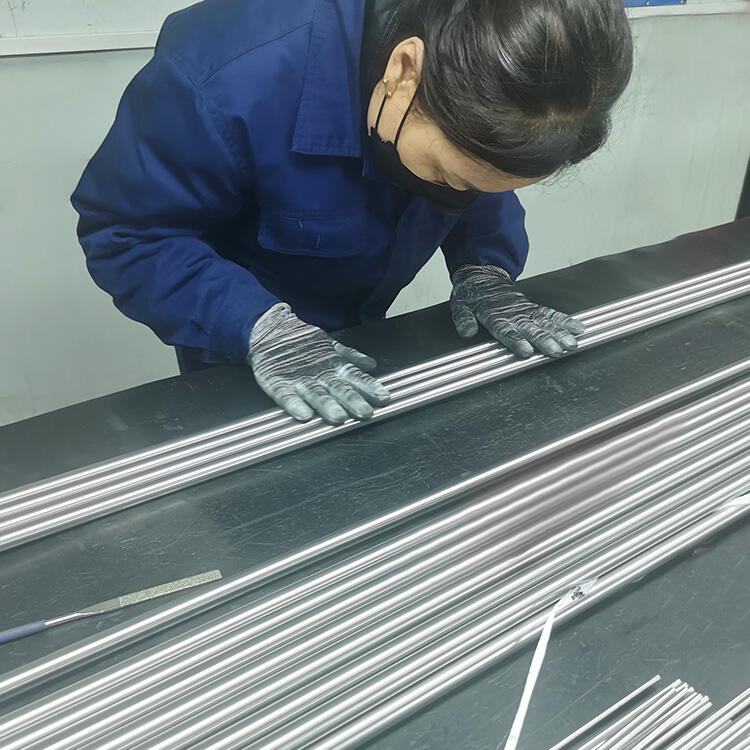

To prevent contamination, we store the titanium bars in a clean, dry environment and protect them from exposure to air, moisture, and other contaminants. We also use appropriate packaging materials to prevent damage during transportation and handling.

When handling the titanium bars, we follow strict procedures to avoid scratching or damaging the surface of the bars. We use clean tools and equipment and wear gloves to prevent the transfer of contaminants from our hands to the bars.

Collaboration with Customers

At our company, we believe that collaboration with our customers is essential for ensuring the purity of titanium bars. We work closely with our customers to understand their specific requirements and to provide them with the best possible solutions.

We are committed to providing high-quality products and excellent customer service. If you have any questions or need further information about our titanium bars, please do not hesitate to contact us. We look forward to working with you and helping you find the perfect titanium bar solution for your needs.

References

· "Titanium: A Technical Guide" by John C. Williams

· "The Kroll Process for Titanium Production" by Donald R. Askill

· "Quality Control in Titanium Production" by Robert J. Cotton

Hot News

Hot News