Baotai road,weibin zone,baoji city, Shaanxi Province,China +86-15399417429 [email protected]

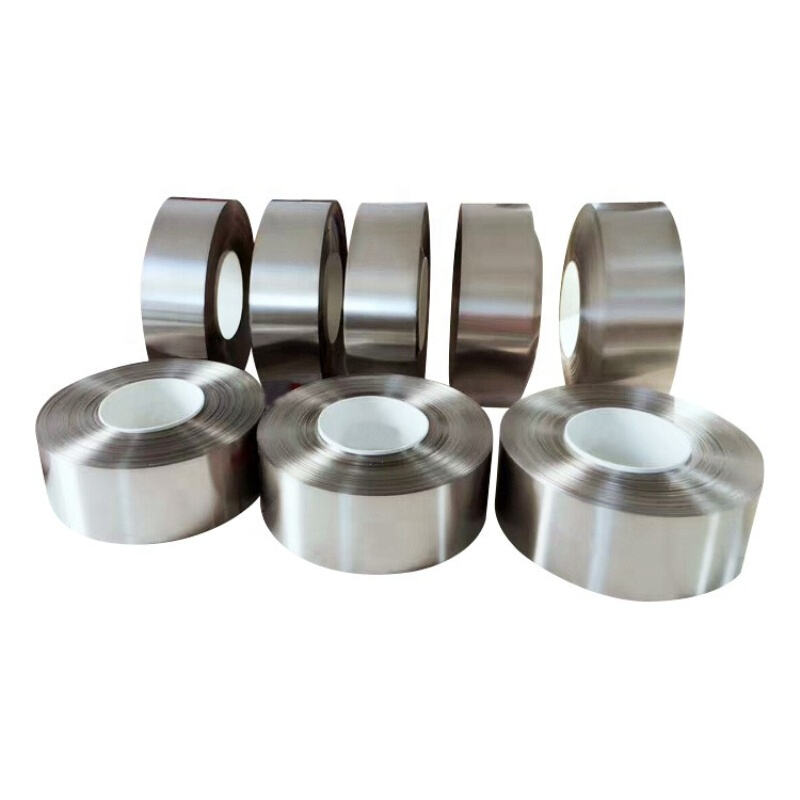

Name: Industrial titanium foil

Material: Titanium and titanium alloy

Standard: ASTM B265

MOQ: 1kg

Grade: Grade1 Grade2 Grade3 Grade4 Grade5

Product status:heating processing, cold processing

Industrial titanium foil

Industrial titanium foil as Ylasting titanium factory main product, we can produce any size and any grade titanium foil, if you have special requirements, we can custom. Titanium Foil is an extremely thin titanium product, usually less than 0.1 mm (100 microns) thick, and the thinnest can reach 0.01 mm (10 microns). It is made of pure titanium or titanium alloy (such as Grade 1, Grade 2, Grade 5) through precision rolling or cold working, and has excellent flexibility, corrosion resistance, thermal conductivity and biocompatibility.

Products Description

Size |

0.025-75MM |

Production Standards |

ASTM B265 / ASME SB265/ AMS 4911 /ASTM F67 / ASTM F136/ISO 5832-2 / ISO 5832-3 |

Titanium Grades |

Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 Ti15333 BT1-00 BT1-0 BT1-2 |

Surface Finishes |

Acid surface or polishing, sand blasted surface |

Extremely thin and light

The thickness of our products can be as low as 0.01 mm, which is much thinner than general metal materials and has excellent flexibility and plasticity. Its low density (about 4.51 g/cm³) gives the product a lightweight advantage, making it easy to process into complex shapes and not easy to break, suitable for precision manufacturing and multi-layer composite applications

Excellent corrosion resistance

Although the thickness of the naturally generated oxide film on the surface of our products is only a few nanometers, it is extremely dense and stable, and can effectively block erosion by various corrosive media, especially in acidic and alkaline environments and seawater. The corrosion rate is less than 0.1 mm/year.

High thermal conductivity

The Titanium Foil have good thermal conductivity, with a thermal conductivity of about 21.9 W/(m·K), which is much better than some stainless steel materials and can be effectively used in heat dissipation and heat exchange equipment. At the same time, its conductive performance is stable, suitable for use as a key material in lithium battery collectors and electrolytic equipment.

Quality Control

Ylasting titanium has advanced production equipment which enables us to meet the varying production requirements of different customers. All products undergo strict third-party inspections before packaging to ensure product quality. The strict packaging requirements further ensure that the quality of the goods remains unaffected until they are delivered to the customers.

Our Service

Size customization: Non-standard width, length, and special cutting.

Can cut any width and length.

Performance customization: Adjust the mechanical properties (such as strength, hardness) and surface conditions (special roughness, coating) according to customer requirements.

Special requirements: Meeting special cleanliness standards, packaging, labeling, and special certifications (such as medical, aerospace certifications), etc.

Applications

The electronics and semiconductor industries

Used for semiconductor coating (PVD/CVD process), as the supporting substrate for high-purity titanium targets, to ensure uniform deposition of the chip's metal layer.

Ultra-high purity (such as Gr1) and ultra-smooth surface (Ra ≤ 0.2 μm).

New Energy and Environmental Protection Technologies

Hydrogen fuel cell bipolar plate

Core function: As an alternative to graphite plates, it possesses conductivity, resistance to hydrogen ion corrosion, and lightweight property (thickness ranging from 0.1 to 0.3 mm).

Process: Surface plating with platinum or carbon coating to enhance conductivity, and forming through stamping to create flow channels.

Chemical Engineering and Medicine

Chemical corrosion protection lining

Adheres to the inner walls of the reactor/pipeline, resisting corrosion from strong acids (hydrochloric acid, sulfuric acid) and chloride ions.

Medical implants

Orthopedics: Spinal fusion devices, bone defect repair nets (Gr2/Gr23 foil materials, thickness 0.1 - 0.5mm).

Oral cavity: The sealing gasket on the base of the dental implant helps prevent microbial invasion.

Pharmaceutical equipment sealing

The gaskets and valve membranes in the aseptic production line are capable of withstanding high-temperature steam sterilization and drug solvents.

Emerging frontier fields

3D printing raw materials

Thin titanium foil serves as an interlayer bonding material in additive manufacturing, enhancing the density of the printed parts (especially in the electron beam melting process).

Superconducting material baseband

The flexible metal substrate of the second-generation high-temperature superconducting tapes (such as YBCO) requires extremely low hysteresis loss.

Photoelectric conversion device

The back electrode or encapsulation layer of perovskite solar cells has much better weather resistance than traditional metal foils.

Copyright © 2026 Xi'an Ylasting Titanium Industry Co.,Ltd. All rights reserved. — Privacy Policy