Baotai road,weibin zone,baoji city, Shaanxi Province,China +86-15399417429 [email protected]

Product name: High-Strength Titanium Round Bar

Material Grade: GR1 Gr2 Gr3 Gr4 Gr5 Gr9 Gr23

Technical standard: ASTM B348

MOQ :1KG/PCS(Min.Order)

Density:4.51g/cm³

Advantage:High strength, corrosion resistance

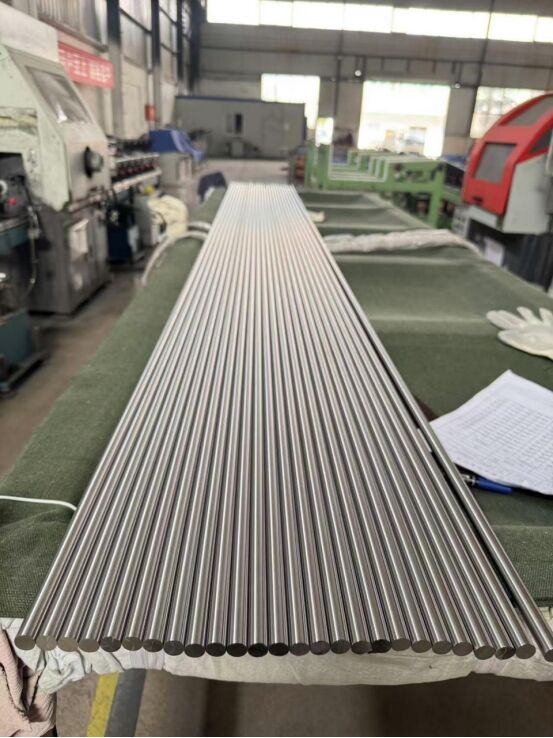

High-Strength Titanium Round Bar

High-Strength Titanium Round Bar is a solid titanium bar with a circular cross-section. It is one of the basic profiles in titanium processing materials and is commonly made of pure titanium metal (such as GR1, GR2) or titanium alloy (Gr5 such as Ti-6Al-4V).

Our product uses Ti-6Al-4V (Grade 5) alloy with a tensile strength of 900-1050 MPa and a density of only 4.5 g/cm³, which is 43% lighter than a stainless steel round bar of the same diameter. Its α+β dual-phase crystal structure optimizes the grain size to 10-15 microns through hot rolling process, which increases the yield strength of the material under axial load by 25%. It is suitable for scenes such as aircraft landing gear and racing drive shafts, achieving a 20%-30% weight reduction for structural parts while maintaining a bending modulus of more than 230 GPa.

High Temperature Stability

The Titanium Round Bar still retains 75% of its room temperature strength at a high temperature of 550°C, and the thermal expansion coefficient is 8.6×10⁻⁶/°C, which is only 1/2 of stainless steel. After β-phase stabilization heat treatment, its creep strength under continuous load at 400°C reaches 100 MPa (5000 hours test data), and the high-temperature deformation rate is less than 0.01%. It is suitable for scenarios such as aircraft engine brackets and nuclear reactor internals, ensuring dimensional stability under extreme temperatures.

Products Description

Chemical composition Titanium round bar&rod

terial grade |

Main component, % |

Impurity content, not more than, % |

|||||||||||

Ti |

Al |

V |

Mo |

Ni |

Pd |

Fe |

C |

N |

H |

O |

residual elementa |

||

single |

sum |

||||||||||||

Gr.1 |

margin |

- |

- |

- |

- |

- |

0.2 |

0.08 |

0.03 |

0.01 |

0.18 |

0.1 |

0.4 |

Gr.2 |

margin |

- |

- |

- |

- |

- |

0.3 |

0.08 |

0.03 |

0.01 |

0.25 |

0.1 |

0.4 |

Gr.3 |

margin |

- |

- |

- |

- |

- |

0.3 |

0.08 |

0.05 |

0.01 |

0.35 |

0.1 |

0.4 |

Gr.4 |

margin |

- |

- |

- |

- |

- |

0.5 |

0.08 |

0.05 |

0.01 |

0.4 |

0.1 |

0.4 |

Gr.5 |

margin |

5.50~6.75 |

3.5~4.5 |

- |

- |

- |

0.4 |

0.08 |

0.05 |

0.01 |

0.2 |

0.1 |

0.4 |

Gr.7 |

margin |

- |

- |

- |

- |

0.12~0.25 |

0.3 |

0.08 |

0.03 |

0.01 |

0.25 |

0.1 |

0.4 |

Gr.9 |

margin |

2.5~3.5 |

2.0~3.0 |

- |

- |

- |

0.25 |

0.08 |

0.03 |

0.01 |

0.15 |

0.1 |

0.4 |

Gr.12 |

margin |

- |

- |

0.2~0.4 |

0.6~0.9 |

- |

0.3 |

0.08 |

0.03 |

0.01 |

0.25 |

0.1 |

0.4 |

Residual elements should include:Al,V,Sn,Mo,Cr,Mn,Zr,Ni,Cu,Si,Y,Nb,Hf,Bi, Ru,Pd, Co,Ta,B,W(The alloy elements contained in this grade should be removed);when it is not specified in the contract,residual elements are not analyzed,report externally according to the standard value. | |||||||||||||

Mechanical properties Titanium round bar

Material grade |

state |

Mechanical properties at room temperature, not less than |

|||

σь |

σo.2 |

δ4D |

ψ |

||

Gr.1 |

Annealing(M) |

241(35) |

172(25) |

24 |

30 |

Gr.2 |

345(50) |

276(40) |

20 |

30 |

|

Gr.3 |

448(65) |

379(55) |

18 |

30 |

|

Gr.4 |

552(80) |

483(70) |

15 |

25 |

|

Gr.5 |

896(130) |

827(120) |

10 |

25 |

|

Gr.7 |

345(50) |

276(40) |

20 |

30 |

|

Gr.9 |

621(90) |

483(70) |

15 |

25 |

|

Gr.12 |

483(70) |

345(50) |

18 |

25 |

|

Products production process

Products production line

Fast delivery within 2days

About titanium round bar we have many stock,please contact us to get what you need.Titanium bar have pure titanium and alloy titanium,different grade have different peculiarity,so let's start to contact us

Custom

It can be customized according to your requirements for titanium and titanium alloy rod or bar.

Quality Check

At Ylasting titanium, titanium rod and bar after production, will be test by QC department, and then send the sample to third-party, all data meet with technical standard, will be packed and shipped out for clients.

Products Stock

Ylasting titanium factory can produce any size and any grade High-Strength Titanium Round Bar and rod, all have stock,can ship out within 2days.

Quality control

Ylasting factory will complete the following key items of testing through internal laboratory testing and third-party testing: chemical composition analysis, mechanical property testing, metallographic analysis, non-destructive testing, dimensional and positional tolerance testing, surface quality inspection, etc. Finally, a standardized and detailed test report is obtained.

Ylasting titanium factory is an excellent supplier of medical titanium round bar in China.It has ten years of experience in titanium production, providing material development and design as well as production to customers worldwide. We can offer titanium bar&rod, plate&sheet,wire,foil,forgings and products.

Copyright © 2026 Xi'an Ylasting Titanium Industry Co.,Ltd. All rights reserved. — Privacy Policy