Baotai road,weibin zone,baoji city, Shaanxi Province,China +86-15399417429 [email protected]

Name:Medical Titanium Round Bar

Material Grade: Grade3 Grade5 Grade23 TI6AL4V-ELI

Technical Standard: ASTM F67 ASTM F136

Material Density: 4.51g/cm³

Tolerance: H11 H9 H7 H6

MOQ: 1KG

Products Description

Professional medical titanium round rod manufacturer,providing high-precision and high-performance titanium material solutions for global wholesale customers. We focus on the production and research and development of titanium rods, strictly adhering to international standards such as ASTM F67 and ASTM F136. We offer titanium rods of various grades including Gr3 Gr5 and Gr23, with diameters ranging from Φ1mm to Φ300mm, tolerances accurate to ±0.01mm, and surface finish Ra≤0.8μm. Ensure that each batch of products has passed spectral analysis and ultrasonic flaw detection testing (with SGS certification). With advanced equipment such as a 2,000-ton fast forging machine and a vacuum consumable arc furnace (VAR), we have achieved a monthly production capacity of 200 tons. Relying on our own sponge titanium supply chain, we offer wholesale customers more competitive prices (8%-12% lower than the market) and stable delivery times (within 10 days for regular sizes).

Product name |

Medical Titanium Round Bar |

Material grade |

GR3 GR5 ELI GR23 TI6AL4V ELI TC4 ELI |

Standard |

ASTM F67 ASTM F136 GB 13810 |

MOQ |

1KG/PCS |

Status |

Annealed state (M), hot working state (R), cold working state (Y) (annealed, ultrasonic flaw detection) |

Tolerance |

H11 H9 H7 H6 |

Production method: |

Forging and hot rolling |

Testing methods |

According to customer requirements, radiographic testing, coloring, flaw detection tests and other tests can be conducted. |

Application |

Surgical instruments and also into accessories for the body of a vegetative person. |

Chemical composition and physical properties

How to determine what a qualified product is? Each standard and grade has its own chemical composition and physical properties to decide whether it is qualified or not.The test data must be within the standard range to be considered qualified. Below is Gr5 Ti 6AL4V Eli Medical Titanium Bar round rod different standard.

Chemical Requirements for ASTMF67

Chemical Requirements for ASTMF67 | ||||

Element |

Composition,%(mass/mass) |

|||

Grade 1 UNS R50250 |

Grade 2 UNS R50400 |

Grade 3 UNS R50550 |

Grade 4 UNS R50700 |

|

Nitrogen, max |

0.03 |

0.03 |

0.05 |

0.05 |

Carbon,max |

0.08 |

0.08 |

0.08 |

0.08 |

Hydrogen,max |

0.015 |

0.015 |

0.015 |

0.015 |

lron, max |

0.2 |

0.3 |

0.3 |

0.5 |

Oxygen,max |

0.18 |

0.25 |

0.35 |

0.4 |

Titanium |

balance |

balance |

balance |

balance |

Chemical Requirements for ASTMF136

Chemical Requirements for ASTMF136 | |

Element |

Composition, %(mass/mass) |

Nitrogen, max |

0.05 |

Carbon,max |

0.08 |

Hydrogen, max |

0.012 |

lron, max |

0.25 |

Oxygen, max |

0.13 |

Aluminum |

5.5-6.50 |

Vanadium |

3.5-4.5 |

Titanium |

balance |

Mechanical properties for ASTMF67 and ASTMF136

ASTM Grade | |||||

Property |

1 |

2 |

3 |

4 |

5 |

Yield Strength (MPa) |

170 |

275 |

380 |

483 |

795 |

Ultimate Tensile Strength (MPa) |

240 |

345 |

450 |

550 |

860 |

Elongation (%) |

24 |

20 |

18 |

15 |

10 |

Elastic Modulus (GPa) |

103-107 |

103-107 |

103-107 |

103-107 |

114-120 |

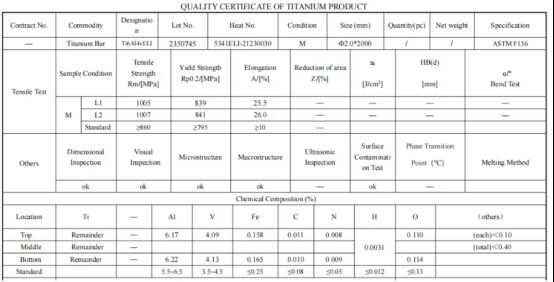

Products test report

We will complete the following key items of testing through internal laboratory testing and third-party testing: chemical composition analysis, mechanical property testing, metallographic analysis, non-destructive testing, dimensional and positional tolerance testing, surface quality inspection, etc. Finally, a standardized and detailed test report is obtained.

Application

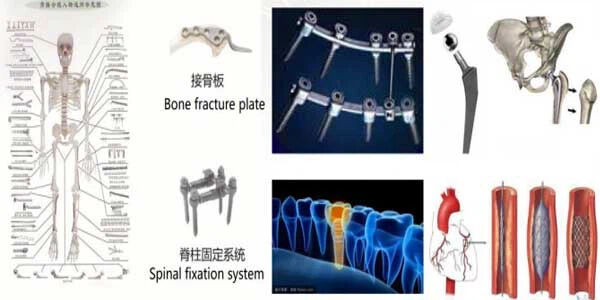

Medical titanium rounbd bar is considered the most attractive metal materials for biomedical applications. Ti-6Al-4V has long been favored for biomedical applications. However, for permanent implant applications, the alloy may have toxic effects due to released vanadium and aluminum. Therefore, vanadium-free and aluminum-free alloys have been introduced for implant applications.

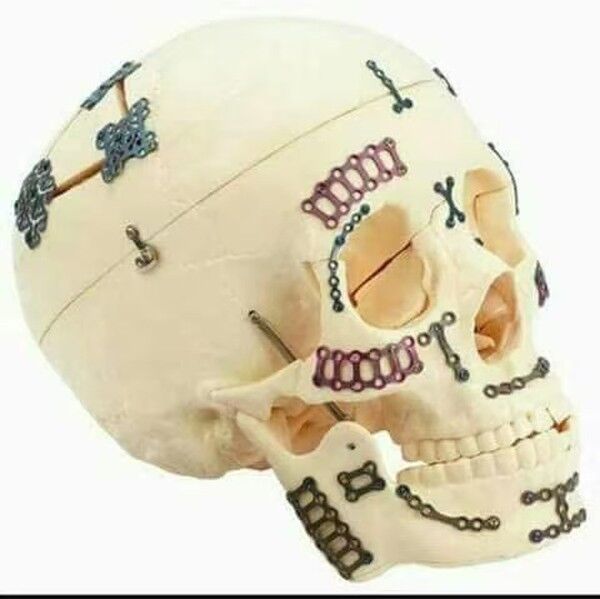

Orthopedic implants

Due to Titanium alloys have excellent biocompatibility, corrosion resistance, and moderate strength features.They are widely used in orthopedic implants, such as artificial joints, fracture fixation instruments, spinal correction equipment, etc.

Orthopedic implants

Because titanium alloys have excellent compatibility with the human body and are non-toxic and harmless to it, they are used in bone joints

Bone nail

Because titanium alloys have excellent compatibility with the human body and are non-toxic and harmless to it, they are used in bone joints

Dental Applications

Titanium alloy is used in dentistry for dental implants, crowns, bridges and inlays. Since the elastic modulus of titanium alloys is similar to that of natural teeth, dental implants made of titanium alloy can reduce the pressure on alveolar bone, improve stability and success rate of implants.

Products Stock

Ylasting titanium factory can produce any size and any grade medical titanium round bar and rod , all have stock,can ship out within 2days.

Copyright © 2026 Xi'an Ylasting Titanium Industry Co.,Ltd. All rights reserved. — Privacy Policy