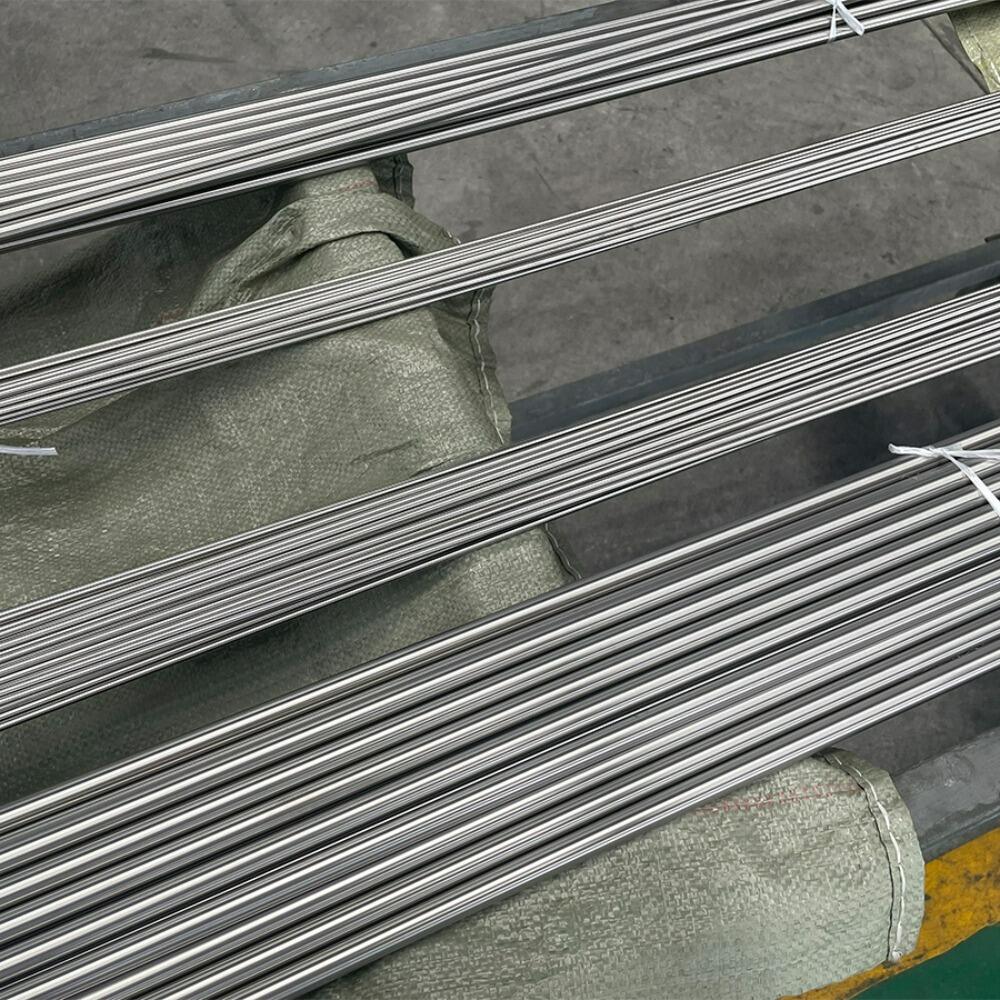

The exceptional properties of titanium straight wire have revolutionized multiple industries, from aerospace manufacturing to advanced medical procedures. This specialized material combines the inherent strength of titanium with precision engineering to create a product that meets the most demanding applications. Industries requiring materials that can withstand extreme conditions while maintaining structural integrity consistently turn to titanium straight wire solutions. The growing demand across sectors demonstrates how this versatile material addresses critical performance requirements that conventional alternatives simply cannot match.

Fundamental Properties Making Titanium Straight Wire Essential

Superior Strength-to-Weight Characteristics

The remarkable strength-to-weight ratio of titanium straight wire sets it apart from traditional metallic alternatives in demanding applications. This unique characteristic allows engineers to design lighter components without compromising structural performance, particularly crucial in aerospace and automotive industries. The material maintains its mechanical properties across wide temperature ranges, ensuring consistent performance in extreme environments. Manufacturing processes have been refined to maximize these inherent advantages, creating products that exceed industry standards for durability and reliability.

Advanced metallurgical techniques enhance the natural properties of titanium straight wire, resulting in products with exceptional tensile strength and fatigue resistance. The precise control over grain structure during production ensures uniform performance characteristics throughout the entire length of the wire. Quality control measures verify that each titanium straight wire meets stringent specifications for aerospace, medical, and industrial applications. These enhanced properties make the material indispensable for applications where failure is not an option.

Corrosion Resistance in Harsh Environments

The outstanding corrosion resistance of titanium straight wire enables its use in chemically aggressive environments where other materials would rapidly deteriorate. This property stems from the formation of a stable oxide layer that protects the underlying metal from further oxidation and chemical attack. Marine applications particularly benefit from this characteristic, as saltwater exposure poses significant challenges for conventional metallic components. The longevity provided by corrosion resistance translates into reduced maintenance costs and improved system reliability.

Chemical processing industries rely heavily on the inert nature of titanium straight wire when handling corrosive substances and extreme pH conditions. The material maintains its integrity when exposed to acids, bases, and organic solvents that would compromise alternative materials. This resistance extends the service life of equipment and reduces the risk of contamination in sensitive processes. The economic benefits of reduced replacement cycles and minimal maintenance requirements make titanium straight wire an attractive long-term investment.

Medical Industry Applications and Advantages

Biocompatibility for Surgical Implants

The exceptional biocompatibility of titanium straight wire makes it the preferred choice for permanent surgical implants and medical devices. The human body readily accepts titanium without triggering adverse immune responses, allowing for successful integration with biological tissues. Orthopedic surgeons utilize this material for bone fixation devices, joint replacements, and spinal fusion hardware where long-term compatibility is essential. The non-toxic nature of titanium eliminates concerns about metal ion release that can occur with other implant materials.

Cardiovascular applications benefit significantly from the use of titanium straight wire in stents, guidewires, and pacemaker components. The material's ability to maintain flexibility while providing necessary support makes it ideal for devices that must function within the dynamic cardiovascular system. Dental implants manufactured from titanium straight wire demonstrate exceptional osseointegration, forming strong bonds with jawbone tissue. The longevity and reliability of these medical applications have established titanium as the gold standard for biomedical implants.

Sterilization and Hygiene Requirements

Medical applications demand materials that can withstand repeated sterilization cycles without degradation, making titanium straight wire particularly valuable for reusable surgical instruments. The material maintains its properties through autoclaving, gamma radiation, and chemical sterilization processes commonly used in healthcare facilities. This durability ensures that medical devices retain their precision and reliability throughout their service life. The smooth surface finish of properly manufactured titanium straight wire resists bacterial adhesion, supporting infection control protocols.

Surgical instruments crafted from titanium straight wire offer surgeons tools that combine lightweight handling with exceptional precision and durability. The material's resistance to staining and discoloration maintains the professional appearance of instruments even after extensive use and sterilization. Quality assurance protocols in medical device manufacturing ensure that every titanium straight wire component meets the stringent requirements for patient safety and device performance. The reliability of these materials contributes to positive surgical outcomes and patient confidence in medical procedures.

Industrial Manufacturing Applications

Aerospace Component Manufacturing

The aerospace industry's demand for materials that perform reliably under extreme conditions has made titanium straight wire indispensable for critical aircraft components. Engine parts manufactured from this material withstand the high temperatures and stresses encountered during flight operations while contributing to overall weight reduction. The excellent fatigue resistance of titanium straight wire ensures that aircraft components maintain their integrity through countless stress cycles. Advanced manufacturing techniques allow for the production of complex geometries that optimize aerodynamic performance and structural efficiency.

Space exploration missions rely on titanium straight wire components that must function flawlessly in the harsh environment of space, where repair options are limited or nonexistent. The material's stability across extreme temperature variations makes it suitable for spacecraft structures that experience dramatic heating and cooling cycles. Satellite components manufactured from titanium straight wire demonstrate the longevity required for multi-year missions in orbit. The reliability and performance characteristics of these applications have established titanium as a cornerstone material in aerospace engineering.

Chemical Processing Equipment

Chemical processing facilities utilize titanium straight wire in applications where exposure to aggressive chemicals would rapidly destroy conventional materials. Heat exchangers, reaction vessels, and piping systems benefit from the material's ability to maintain structural integrity while resisting chemical attack. The smooth surface finish of titanium straight wire reduces fouling and facilitates cleaning procedures in sanitary applications. Process engineers specify this material for critical applications where equipment failure could result in production losses or safety hazards.

Pharmaceutical manufacturing requires materials that meet strict purity standards while withstanding cleaning and sterilization protocols, making titanium straight wire an ideal choice for process equipment. The material's inert nature prevents contamination of pharmaceutical products, ensuring compliance with regulatory requirements. Quality control systems verify that titanium straight wire components meet the exacting standards required for pharmaceutical applications. The long service life and minimal maintenance requirements of these installations provide significant economic advantages to manufacturing operations.

Manufacturing Processes and Quality Control

Advanced Production Techniques

Modern manufacturing processes for titanium straight wire incorporate sophisticated techniques that ensure consistent quality and performance characteristics throughout production runs. Cold drawing and annealing processes are carefully controlled to achieve the desired mechanical properties while maintaining dimensional accuracy. State-of-the-art equipment enables the production of titanium straight wire with extremely tight tolerances, meeting the precision requirements of demanding applications. Continuous process monitoring ensures that every meter of produced wire meets established specifications.

Surface treatment processes enhance the natural properties of titanium straight wire, providing improved wear resistance and surface finish quality. Specialized cleaning procedures remove any surface contaminants that could compromise performance in critical applications. Heat treatment protocols are precisely controlled to optimize the microstructure and mechanical properties of the final product. These advanced manufacturing techniques result in titanium straight wire that consistently exceeds industry standards for quality and performance.

Testing and Certification Standards

Comprehensive testing protocols verify that titanium straight wire meets the stringent requirements for aerospace, medical, and industrial applications. Mechanical testing includes tensile strength, yield strength, and fatigue resistance measurements to ensure material properties conform to specifications. Chemical analysis verifies the purity and composition of titanium straight wire, confirming compliance with industry standards and customer requirements. Non-destructive testing methods detect any internal defects that could compromise performance in service.

Certification processes for titanium straight wire involve rigorous documentation and traceability systems that track materials from raw material receipt through final product delivery. Quality management systems ensure that all manufacturing processes are controlled and monitored to maintain consistent product quality. Third-party testing and certification provide additional assurance that titanium straight wire products meet international standards and regulatory requirements. These comprehensive quality systems give customers confidence in the reliability and performance of their titanium straight wire purchases.

Economic Benefits and Cost Considerations

Lifecycle Cost Analysis

The initial investment in titanium straight wire often proves economical when evaluated over the complete lifecycle of an application. Extended service life and minimal maintenance requirements offset higher material costs, particularly in critical applications where downtime carries significant economic penalties. Reliability studies demonstrate that titanium straight wire components typically outlast alternatives by factors of three to five in demanding environments. The reduced frequency of replacements and associated labor costs contribute to favorable total cost of ownership calculations.

Energy efficiency gains from lighter weight titanium straight wire components provide ongoing operational savings in transportation and mobile applications. Fuel consumption reductions in aircraft and vehicles equipped with titanium components generate cost savings that accumulate over the operational life of the equipment. Reduced maintenance intervals and simplified inspection procedures further contribute to the economic advantages of specifying titanium straight wire. These financial benefits often justify the selection of titanium over less expensive alternatives in performance-critical applications.

Supply Chain and Availability

The global supply chain for titanium straight wire has evolved to support growing demand across multiple industries, with established suppliers maintaining strategic inventory levels. Reliable delivery schedules and consistent quality have made titanium straight wire a dependable material choice for production planning. Just-in-time manufacturing strategies benefit from the predictable availability and standardized specifications of quality titanium straight wire products. Supply chain partnerships between manufacturers and suppliers ensure continuity of supply for critical applications.

Market developments in titanium processing technology continue to improve the cost-effectiveness and availability of titanium straight wire products. Economies of scale in production facilities have contributed to more competitive pricing while maintaining quality standards. Recycling programs for titanium materials support sustainability initiatives while providing cost-effective raw material sources. These market dynamics create favorable conditions for increased adoption of titanium straight wire across diverse industrial applications.

Future Developments and Innovation

Emerging Applications and Technologies

Emerging technologies in additive manufacturing are expanding the potential applications for titanium straight wire in custom and low-volume production scenarios. Three-dimensional printing processes utilizing titanium feedstock enable the creation of complex geometries that were previously impossible to manufacture economically. Research into hybrid manufacturing techniques combines traditional wire processing with additive methods to create innovative product designs. These technological advances are opening new markets and applications for titanium straight wire products.

Renewable energy applications increasingly specify titanium straight wire for components that must withstand harsh environmental conditions while maintaining long service lives. Wind turbine components, solar panel mounting systems, and energy storage devices benefit from the durability and corrosion resistance of titanium materials. Electric vehicle manufacturers are exploring the use of titanium straight wire in battery systems and structural components to reduce weight while improving safety. These emerging applications represent significant growth opportunities for titanium straight wire suppliers.

Research and Development Initiatives

Ongoing research programs focus on enhancing the properties of titanium straight wire through advanced alloy development and processing improvements. Nanotechnology applications are being explored to create surface treatments that provide additional functionality while maintaining the base properties of titanium. Collaborative research between universities and industry aims to develop new grades of titanium straight wire optimized for specific applications. These development efforts promise to expand the range of applications where titanium provides superior performance.

Environmental considerations drive research into more sustainable production methods for titanium straight wire, including reduced energy consumption and waste minimization. Recycling technology improvements are making it more economical to reclaim and reprocess titanium materials, supporting circular economy principles. Life cycle assessment studies help optimize the environmental impact of titanium straight wire throughout its entire service life. These sustainability initiatives align with corporate environmental goals while maintaining the performance advantages of titanium materials.

FAQ

What makes titanium straight wire different from other metal wires

Titanium straight wire offers a unique combination of high strength, low weight, and exceptional corrosion resistance that sets it apart from conventional metal wires. The biocompatibility of titanium makes it suitable for medical applications where other metals would be rejected by the human body. Its ability to maintain properties across extreme temperature ranges exceeds the capabilities of steel, aluminum, and most other metallic alternatives. The superior fatigue resistance ensures longer service life in applications involving repeated stress cycles.

How does the cost of titanium straight wire compare to alternatives

While titanium straight wire typically costs more initially than steel or aluminum alternatives, the total lifecycle cost often favors titanium due to its extended service life and minimal maintenance requirements. The reduced weight of titanium components can provide ongoing operational savings in transportation applications through improved fuel efficiency. Lower replacement frequency and reduced downtime for maintenance contribute to favorable economics in critical applications. The premium price is justified by superior performance and reliability in demanding environments.

What quality certifications are available for titanium straight wire

Titanium straight wire can be certified to various international standards including ASTM, AMS, and ISO specifications depending on the intended application. Medical grade materials meet FDA requirements and biocompatibility standards for implantable devices. Aerospace applications require certifications that demonstrate compliance with aviation authority regulations and material specifications. Traceability documentation provides complete material history from raw material source through final product delivery.

What are the typical lead times for titanium straight wire orders

Standard titanium straight wire products typically have lead times of 4-8 weeks depending on diameter, length, and quantity requirements. Custom specifications or special processing may require additional time for engineering review and production setup. Established suppliers often maintain inventory of common sizes to support faster delivery for standard applications. Rush orders may be accommodated for critical applications, though premium pricing typically applies for expedited production and shipping.