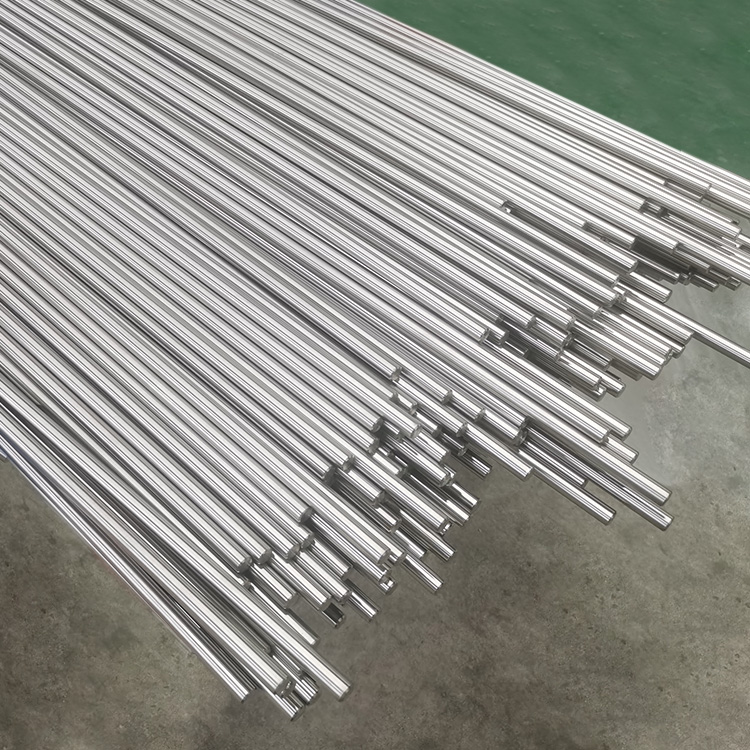

In today's competitive industrial landscape, manufacturers and engineers are constantly seeking materials that deliver exceptional performance while maintaining economic viability. The titanium round rod has emerged as a game-changing solution that perfectly balances superior material properties with long-term cost advantages. Despite titanium's reputation as a premium material, modern production techniques and market dynamics have made titanium round rods increasingly accessible to a broader range of applications, from aerospace engineering to medical device manufacturing.

The cost-effectiveness of titanium round rods extends far beyond their initial purchase price, encompassing factors such as operational longevity, maintenance reduction, and performance optimization. Industries worldwide are recognizing that the upfront investment in titanium round rod solutions often translates to significant savings over the product lifecycle. This shift in perspective has driven increased adoption across sectors where reliability, durability, and performance are paramount considerations.

Superior Material Properties Drive Long-Term Value

Exceptional Strength-to-Weight Ratio

The outstanding strength-to-weight ratio of titanium round rod applications makes them invaluable for weight-critical projects. This unique characteristic allows engineers to design lighter structures without compromising structural integrity, resulting in reduced material usage and lower transportation costs. In aerospace applications, every gram saved translates to fuel efficiency gains that accumulate substantial cost savings over operational lifetimes.

Manufacturing processes benefit significantly from titanium's lightweight nature, as handling equipment requires less power and wear on machinery is reduced. The ease of manipulation during fabrication processes decreases labor costs and improves overall production efficiency. Additionally, the reduced weight of finished products often eliminates the need for specialized heavy-duty installation equipment, further contributing to project cost reductions.

Outstanding Corrosion Resistance

Titanium round rods demonstrate remarkable resistance to corrosion in harsh environments, including saltwater, acidic conditions, and extreme temperatures. This natural corrosion resistance eliminates the need for expensive protective coatings and frequent maintenance schedules that plague traditional materials like steel or aluminum. The protective oxide layer that forms naturally on titanium surfaces provides self-healing properties, ensuring long-lasting protection without additional treatments.

Industries operating in corrosive environments, such as chemical processing and marine applications, realize substantial cost savings through reduced replacement cycles and minimal maintenance requirements. The elimination of coating applications and regular surface treatments significantly reduces operational expenses while improving system reliability. These factors contribute to lower total cost of ownership calculations that favor titanium round rod solutions over traditional alternatives.

Extended Service Life Reduces Replacement Costs

Fatigue Resistance and Durability

The exceptional fatigue resistance of titanium round rod materials ensures extended service life even under cyclic loading conditions. This property is particularly valuable in applications involving repetitive stress cycles, where traditional materials might fail prematurely. The ability to withstand millions of stress cycles without degradation translates directly to reduced replacement frequencies and lower lifecycle costs.

Engineering studies consistently demonstrate that titanium components can operate for decades without significant performance degradation. This longevity factor becomes increasingly important in applications where component replacement involves complex disassembly procedures or system downtime. The reduced need for preventive replacements allows organizations to optimize maintenance schedules and allocate resources more efficiently.

Temperature Stability and Performance

Titanium round rods maintain their mechanical properties across wide temperature ranges, from cryogenic conditions to elevated temperatures exceeding 400°C. This temperature stability eliminates the need for material changes based on operating conditions, simplifying inventory management and reducing procurement costs. The consistent performance characteristics across temperature ranges also minimize the risk of unexpected failures due to thermal cycling.

High-temperature applications particularly benefit from titanium's retained strength at elevated temperatures, where other materials would require oversizing or frequent replacement. The ability to operate reliably in extreme temperature environments reduces the need for auxiliary cooling or heating systems, contributing to overall system cost reductions and energy efficiency improvements.

Manufacturing and Processing Advantages

Machinability and Fabrication Benefits

Modern titanium round rod products exhibit improved machinability compared to earlier titanium alloys, reducing processing time and tooling costs. Advanced metallurgical techniques have optimized the microstructure to facilitate easier cutting, drilling, and forming operations. These improvements translate to reduced manufacturing time and lower production costs for end users.

The predictable machining characteristics of titanium round rods allow for precise manufacturing tolerances and reduced waste during fabrication processes. Consistent material properties eliminate the need for extensive testing and quality control measures required with less reliable materials. This predictability enables manufacturers to optimize their processes and reduce overall production costs.

Weldability and Joining Techniques

Titanium round rods demonstrate excellent weldability when proper techniques are employed, enabling cost-effective joining methods for complex assemblies. The compatibility with various welding processes, including TIG and electron beam welding, provides flexibility in manufacturing approaches. Proper welding procedures produce joints that maintain the parent material's strength and corrosion resistance properties.

The ability to create reliable welded joints reduces the need for mechanical fasteners and complex connection systems, simplifying assembly processes and reducing part counts. This simplification translates to lower manufacturing complexity, reduced inventory requirements, and improved assembly efficiency. The resulting cost savings often offset the initial material investment in titanium round rod applications.

Market Dynamics and Supply Chain Efficiency

Improved Production Technologies

Advances in titanium production technologies have significantly reduced manufacturing costs, making titanium round rod products more economically competitive. Innovations in smelting, forging, and processing techniques have improved yield rates and reduced waste generation during production. These technological improvements have been passed through the supply chain, resulting in more favorable pricing for end users.

The development of more efficient extraction and processing methods has stabilized titanium pricing and improved supply chain reliability. Consistent availability and predictable pricing enable better project planning and budget management for organizations considering titanium round rod applications. The improved supply chain dynamics have eliminated many of the cost uncertainties previously associated with titanium procurement.

Economies of Scale and Market Competition

Increased demand for titanium round rod applications has driven economies of scale in production, resulting in more competitive pricing structures. As more manufacturers enter the market, healthy competition has emerged that benefits end users through improved quality and service offerings. The expanded supplier base also provides greater procurement flexibility and negotiating leverage for large-volume users.

Standardization of titanium round rod specifications has enabled more efficient production runs and inventory management throughout the supply chain. These efficiencies translate to cost reductions that are shared with customers, making titanium solutions more accessible to a broader range of applications and industries.

Industry-Specific Cost Benefits

Aerospace and Defense Applications

The aerospace industry has extensively validated the cost-effectiveness of titanium round rod components through decades of successful applications. Weight savings achieved through titanium implementation translate to reduced fuel consumption, increased payload capacity, and improved operational efficiency. These benefits accumulate over aircraft lifetimes, generating substantial returns on investment.

Defense applications particularly value titanium's combination of strength, weight savings, and corrosion resistance in demanding operational environments. The reduced maintenance requirements and extended service life of titanium components contribute to improved mission readiness and reduced logistics burdens. These operational advantages translate to measurable cost savings in military applications.

Medical and Biomedical Sectors

Medical device manufacturers increasingly rely on titanium round rod materials for implants and surgical instruments due to their biocompatibility and longevity. The extended service life of titanium medical devices reduces the need for revision surgeries, resulting in significant healthcare cost savings. The material's compatibility with sterilization processes also eliminates concerns about degradation from repeated cleaning cycles.

The predictable performance and reliability of titanium medical devices contribute to improved patient outcomes and reduced liability risks. These factors translate to tangible economic benefits for healthcare providers and device manufacturers, justifying the initial material investment through improved long-term outcomes.

FAQ

How does the initial cost of titanium round rod compare to traditional materials?

While titanium round rod materials typically have higher upfront costs compared to steel or aluminum, the total cost of ownership calculations often favor titanium due to extended service life, reduced maintenance requirements, and superior performance characteristics. The initial investment is typically recovered through operational savings within the first few years of service.

What factors should be considered when evaluating titanium round rod cost-effectiveness?

Key factors include service life expectations, maintenance costs, weight savings benefits, corrosion resistance requirements, and replacement frequency. Additionally, consider fabrication costs, availability of specialized processing capabilities, and the impact of improved performance on overall system efficiency when conducting cost-benefit analyses.

Are there specific applications where titanium round rod provides the greatest cost advantages?

Applications involving harsh environmental conditions, weight-critical designs, extended service life requirements, and minimal maintenance access provide the greatest cost advantages for titanium round rod implementations. Industries such as aerospace, marine, chemical processing, and medical devices typically realize the most significant economic benefits from titanium solutions.

How do recent market developments affect titanium round rod pricing trends?

Improved production technologies, increased market competition, and economies of scale have contributed to more favorable pricing trends for titanium round rod products. Supply chain improvements and standardization efforts have also enhanced price stability and reduced procurement uncertainties, making titanium solutions more economically attractive for a broader range of applications.

Table of Contents

- Superior Material Properties Drive Long-Term Value

- Extended Service Life Reduces Replacement Costs

- Manufacturing and Processing Advantages

- Market Dynamics and Supply Chain Efficiency

- Industry-Specific Cost Benefits

-

FAQ

- How does the initial cost of titanium round rod compare to traditional materials?

- What factors should be considered when evaluating titanium round rod cost-effectiveness?

- Are there specific applications where titanium round rod provides the greatest cost advantages?

- How do recent market developments affect titanium round rod pricing trends?