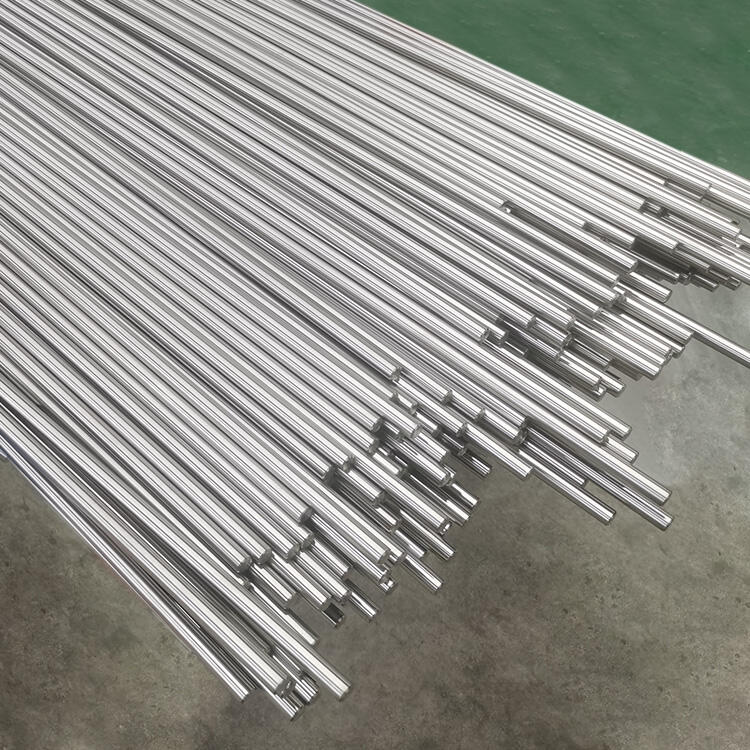

The modern industrial landscape demands materials that can withstand extreme conditions while maintaining structural integrity and performance. Among the most versatile and sought-after materials in contemporary manufacturing, titanium rods have emerged as critical components across numerous sectors. These exceptional metal products combine unparalleled strength-to-weight ratios with remarkable corrosion resistance, making them indispensable for applications where conventional materials fall short. From aerospace engineering to medical device manufacturing, titanium rods serve as the backbone of innovation in industries that push the boundaries of what's possible.

Aerospace and Aviation Industries

Commercial Aircraft Manufacturing

The aerospace industry represents one of the largest consumers of titanium rods globally, with commercial aircraft manufacturers relying heavily on these materials for critical structural components. Aircraft engines, landing gear systems, and fuselage frameworks all incorporate titanium rods due to their exceptional performance characteristics. The ability of titanium to maintain strength at high temperatures makes it ideal for engine components that must endure extreme heat cycles during flight operations. Boeing and Airbus, among other major manufacturers, specify titanium rods for components where weight reduction directly translates to fuel efficiency improvements.

Engine manufacturers particularly value titanium rods for compressor blades, turbine components, and structural supports within jet engines. These applications demand materials that can withstand temperatures exceeding 600 degrees Celsius while maintaining dimensional stability under intense mechanical stress. The corrosion resistance of titanium ensures these components remain functional throughout extended service intervals, reducing maintenance costs and improving aircraft reliability.

Military and Defense Applications

Defense contractors and military aerospace programs utilize titanium rods extensively in fighter aircraft, helicopters, and missile systems. The material's radar-transparent properties and electromagnetic compatibility make it valuable for stealth applications where traditional metals might compromise operational effectiveness. Military specifications often require materials that can perform reliably under combat conditions, including exposure to harsh environments and extreme temperature variations.

Helicopter rotor systems benefit significantly from titanium rod construction, as the material's fatigue resistance ensures safe operation under the cyclic loading conditions inherent in rotorcraft flight. The defense industry's emphasis on performance over cost considerations makes titanium rods a preferred choice for applications where failure is not an option.

Medical and Biomedical Sectors

Orthopedic Implants and Prosthetics

The medical device industry has embraced titanium rods as a cornerstone material for orthopedic applications, particularly in joint replacement surgeries and bone repair procedures. Titanium's biocompatibility ensures that implanted devices integrate seamlessly with human tissue without triggering adverse immune responses. Hip and knee replacement systems commonly incorporate titanium rods as structural elements that must withstand decades of patient activity while maintaining mechanical integrity.

Spinal fusion procedures rely on titanium rods to provide the structural support necessary for vertebrae stabilization. These medical applications demand materials with elastic modulus values that closely match human bone, preventing stress shielding effects that could compromise long-term patient outcomes. The non-magnetic properties of titanium also make it compatible with magnetic resonance imaging procedures, allowing doctors to monitor patient progress without removing implanted devices.

Surgical Instruments and Equipment

Precision surgical instruments manufactured from titanium rods offer surgeons tools that combine exceptional sharpness retention with complete sterilization compatibility. Operating room environments require instruments that can withstand repeated autoclave sterilization cycles without degradation or corrosion. Titanium's chemical inertness ensures that surgical tools maintain their precision characteristics throughout extended service life.

Dental implant systems represent another significant application area where titanium rods provide the foundation for tooth replacement procedures. The osseointegration properties of titanium allow direct bone attachment to implant surfaces, creating permanent solutions for patients with missing teeth. Dental manufacturers specify titanium rods for implant posts that must support chewing forces while remaining stable within jaw bone structures.

Chemical Processing and Industrial Applications

Corrosive Environment Operations

Chemical processing facilities operating with highly corrosive substances rely on titanium rods for equipment components that must resist degradation from acids, bases, and oxidizing agents. Process piping systems, heat exchangers, and reactor vessels incorporate titanium rods in applications where stainless steel and other conventional materials would fail rapidly. The chlor-alkali industry, in particular, depends on titanium components for electrochemical processes that generate aggressive chemical environments.

Petroleum refining operations utilize titanium rods in desalination units and hydrogen processing equipment where salt water and hydrogen sulfide create challenging operating conditions. These applications benefit from titanium's resistance to chloride-induced stress corrosion cracking, a failure mode that affects many other structural materials. The long-term cost effectiveness of titanium rods in these environments often justifies their higher initial investment compared to alternative materials.

Heat Exchanger and Thermal Management Systems

Industrial heat transfer applications frequently specify titanium rods for heat exchanger tube construction and thermal management systems. The material's excellent thermal conductivity combined with corrosion resistance makes it ideal for applications involving seawater cooling, chemical heat recovery, and high-temperature process heating. Power generation facilities, particularly those using seawater cooling systems, rely on titanium rods to maintain heat exchanger efficiency over extended operating periods.

Geothermal energy systems represent an emerging market for titanium rods, as these installations must handle corrosive geothermal fluids at elevated temperatures. The combination of thermal cycling and chemical exposure in geothermal applications creates demanding service conditions that titanium rods handle effectively where other materials would require frequent replacement.

Marine and Offshore Industries

Shipbuilding and Naval Construction

The marine industry utilizes titanium rods extensively in submarine construction, surface vessel propulsion systems, and offshore platform structures. Seawater's corrosive nature creates challenging environments where conventional steel components suffer from galvanic corrosion and pitting attacks. Titanium rods provide the structural integrity necessary for critical marine applications while maintaining performance throughout extended ocean service.

Submarine pressure hull components benefit from titanium's strength characteristics, allowing designers to reduce wall thickness while maintaining structural safety margins. This weight reduction translates directly to improved vessel performance and operational capability. Naval shipyards specify titanium rods for propeller shafts, rudder systems, and hull penetrations where seawater exposure demands superior corrosion resistance.

Offshore Oil and Gas Operations

Offshore drilling platforms and subsea production equipment rely on titanium rods for components exposed to seawater and hydrocarbon environments. Deep water operations create extreme pressure and corrosion conditions that challenge conventional materials. Titanium rods provide the reliability necessary for offshore equipment that must operate continuously in remote locations where maintenance access is limited and costly.

Subsea wellhead equipment and pipeline connections utilize titanium rods in applications where hydrogen sulfide and carbon dioxide create sour service conditions. These corrosive gases can cause rapid degradation of steel components, making titanium rods essential for maintaining operational integrity in challenging offshore environments. The material's resistance to hydrogen embrittlement ensures long-term structural reliability in these demanding applications.

Sports and Recreation Equipment Manufacturing

High-Performance Athletic Equipment

Professional sports equipment manufacturers have adopted titanium rods for applications requiring exceptional strength-to-weight ratios and durability. Golf club shafts, tennis racket frames, and bicycle components all benefit from titanium's performance characteristics. The material's ability to absorb vibration while maintaining stiffness creates superior playing characteristics that athletes demand in competitive environments.

Cycling industry applications include titanium rods in high-end bicycle frames, where the material's fatigue resistance ensures long service life under the repetitive loading conditions of competitive cycling. Mountain bike components particularly benefit from titanium's impact resistance and corrosion immunity when exposed to harsh outdoor conditions. Professional cycling teams often specify titanium rods for custom frame construction that must withstand the rigors of professional competition.

Marine Recreation and Water Sports

Recreational marine equipment manufacturers utilize titanium rods in sailboat rigging, yacht hardware, and diving equipment applications. The saltwater environment of marine recreation creates corrosion challenges that titanium rods handle effectively throughout extended service periods. Sailing hardware such as turnbuckles, cleats, and winch components benefit from titanium's strength and corrosion resistance in marine environments.

Diving equipment applications include titanium rods in regulator components and underwater camera housing structures. These applications demand materials that maintain performance characteristics under high pressure conditions while resisting seawater corrosion. The non-magnetic properties of titanium rods also benefit underwater navigation equipment and scientific instruments used in marine research applications.

FAQ

What makes titanium rods superior to steel in industrial applications

Titanium rods offer several key advantages over steel including superior corrosion resistance, higher strength-to-weight ratio, and better performance at elevated temperatures. While steel may be more cost-effective initially, titanium rods provide longer service life and reduced maintenance requirements in challenging environments, often resulting in lower total cost of ownership over the component lifecycle.

How do titanium rods perform in high-temperature applications

Titanium rods maintain their structural integrity and mechanical properties at temperatures up to 600 degrees Celsius, making them suitable for aerospace engines, chemical processing equipment, and high-temperature industrial applications. The material's thermal expansion characteristics and oxidation resistance ensure dimensional stability and performance reliability in demanding thermal environments.

Are titanium rods suitable for marine environments

Yes, titanium rods excel in marine applications due to their exceptional resistance to seawater corrosion and chloride-induced stress cracking. Unlike steel or aluminum, titanium rods do not require protective coatings or cathodic protection systems when exposed to seawater, making them ideal for shipbuilding, offshore platforms, and marine equipment manufacturing.

What factors should be considered when selecting titanium rods for specific applications

Key selection factors include the specific titanium grade required for the application, environmental conditions such as temperature and corrosive exposure, mechanical loading requirements, and compatibility with joining methods such as welding or mechanical fastening. The total cost of ownership including initial material cost, fabrication requirements, and expected service life should also be evaluated when comparing titanium rods to alternative materials.