Understanding the Revolutionary Impact of Titanium Technology in Modern Medicine

The medical field has witnessed remarkable advancements in implant technology, with medical titanium rods emerging as a groundbreaking solution for various surgical procedures. These innovative components have transformed the landscape of orthopedic and dental surgeries, offering patients unprecedented levels of recovery and mobility. The integration of medical titanium rods in contemporary medical procedures represents a perfect fusion of scientific innovation and practical application, delivering outcomes that were once considered impossible.

Medical professionals worldwide have embraced these remarkable implants for their exceptional properties and consistent performance in diverse medical applications. From spinal fusion surgeries to complex reconstructive procedures, medical titanium rods have proven their worth in countless clinical scenarios, establishing themselves as the gold standard in implant materials.

Essential Properties of Medical Titanium Rods

Biocompatibility and Integration

One of the most significant advantages of medical titanium rods lies in their exceptional biocompatibility. The human body readily accepts titanium, showing minimal risk of rejection or adverse reactions. This natural compatibility allows for seamless integration with existing bone structure, promoting faster healing and reducing recovery time for patients. The surface of medical titanium rods actually encourages osseointegration – the direct structural and functional connection between living bone tissue and the implant surface.

The interaction between titanium and human tissue creates a stable, long-lasting bond that supports the surrounding structures while maintaining their integrity. This remarkable characteristic makes medical titanium rods particularly valuable in procedures requiring permanent implantation, such as spinal fusion surgery or major joint replacements.

Structural Strength and Durability

Medical titanium rods exhibit an impressive strength-to-weight ratio that makes them ideal for load-bearing applications. Despite being significantly lighter than traditional medical implant materials, these rods demonstrate exceptional structural integrity and resistance to deformation. This combination of strength and lightweight properties ensures that patients can maintain their mobility while benefiting from the support these implants provide.

The durability of medical titanium rods extends well beyond initial implementation, with many implants maintaining their structural properties for decades. This longevity significantly reduces the need for revision surgeries and provides patients with lasting solutions to their medical conditions.

Clinical Applications and Surgical Benefits

Orthopedic Surgery Applications

In orthopedic procedures, medical titanium rods have revolutionized treatment approaches for various conditions. They serve as essential components in spinal fusion surgeries, providing necessary support while allowing for natural bone growth and healing. The versatility of these implants enables surgeons to address complex fractures, deformities, and degenerative conditions with greater precision and predictability.

The implementation of medical titanium rods in trauma surgery has particularly transformed the treatment of severe fractures. Their ability to stabilize broken bones while promoting proper healing has significantly improved patient outcomes and reduced recovery times. The adaptability of these implants allows surgeons to customize treatments based on individual patient needs and specific injury patterns.

Dental and Maxillofacial Applications

In dental and maxillofacial surgery, medical titanium rods serve as the foundation for various restorative procedures. They provide stable anchoring points for dental prosthetics and support facial reconstruction efforts. The biocompatibility of titanium is particularly crucial in the oral environment, where the material must withstand constant exposure to various biological factors while maintaining its structural integrity.

The success rate of dental implants utilizing medical titanium rods is remarkably high, thanks to their excellent osseointegration properties and resistance to corrosion in the oral cavity. This reliability has made them the preferred choice for dental professionals worldwide.

Advanced Manufacturing and Quality Control

Precision Engineering Processes

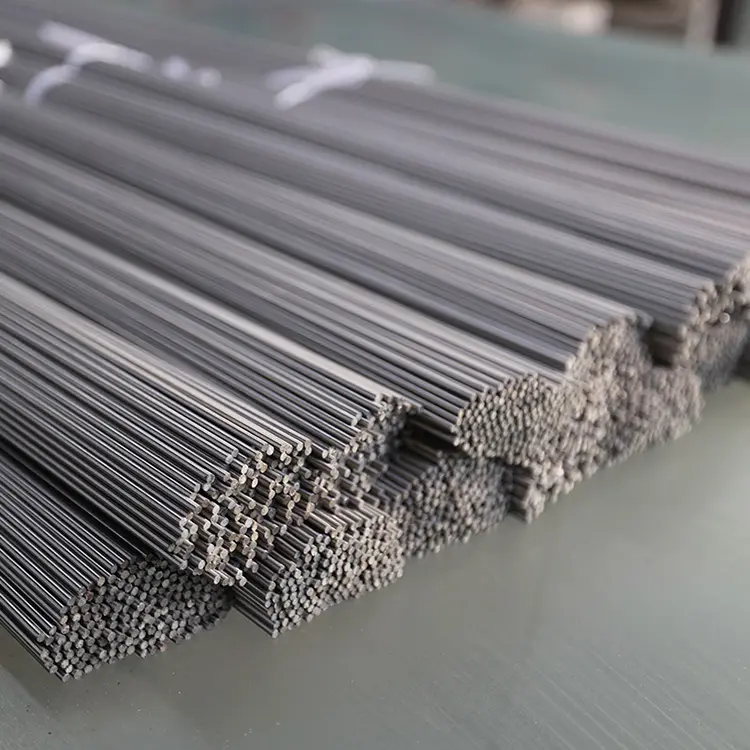

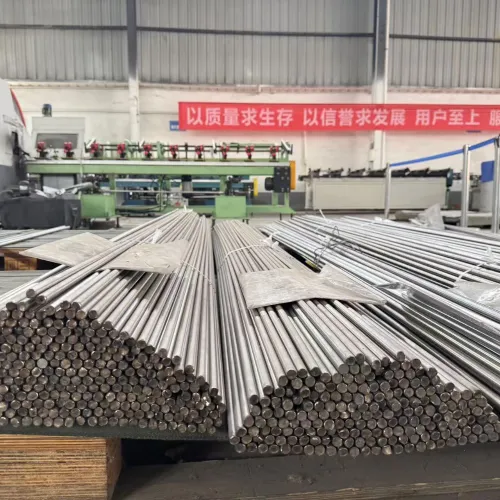

The production of medical titanium rods involves sophisticated manufacturing processes that ensure consistent quality and performance. Advanced computer-aided design and manufacturing techniques allow for precise control over dimensions and surface characteristics. This level of precision is crucial for creating implants that meet the exact specifications required for successful surgical outcomes.

Quality control measures in the manufacturing process include rigorous testing of material properties, surface finish, and dimensional accuracy. Each medical titanium rod undergoes extensive inspection to ensure it meets the stringent standards required for medical implants.

Surface Treatment Technologies

Modern surface treatment technologies enhance the performance of medical titanium rods through specialized coating and texturing processes. These treatments can improve osseointegration, reduce friction, and enhance the overall biocompatibility of the implants. Innovations in surface modification continue to expand the possibilities for improving implant performance and patient outcomes.

Recent developments in nano-surface treatments have shown promising results in accelerating the healing process and strengthening the bond between implant and bone tissue. These advancements represent the cutting edge of medical titanium rod technology and point toward even more exciting possibilities in the future.

Future Developments and Innovations

Emerging Technologies

The field of medical titanium rod development continues to evolve with new technologies and applications emerging regularly. Researchers are exploring advanced alloy compositions and manufacturing techniques to create implants with enhanced properties and functionality. These innovations promise to further improve patient outcomes and expand the range of treatable conditions.

The integration of smart technologies with medical titanium rods is an particularly exciting area of development. Sensors and monitoring systems embedded within implants could provide real-time data about healing progress and implant performance, allowing for more personalized and effective treatment approaches.

Sustainable Manufacturing Practices

The medical device industry is increasingly focusing on sustainable manufacturing practices for medical titanium rods. New recycling technologies and efficient production methods are being developed to reduce environmental impact while maintaining the highest quality standards. These initiatives demonstrate a commitment to responsible manufacturing without compromising on product excellence.

Advances in 3D printing technology are also revolutionizing the production of medical titanium rods, allowing for more customized solutions and reduced waste in the manufacturing process. This approach not only improves sustainability but also enables the creation of more precisely tailored implants for individual patients.

Frequently Asked Questions

How long do medical titanium rod implants typically last?

Medical titanium rod implants are designed for long-term use and can last several decades or even a lifetime with proper care and maintenance. Their durability and resistance to wear make them an excellent choice for permanent implantation, though individual results may vary based on factors such as patient activity level and overall health.

Are there any risks associated with titanium implants?

While medical titanium rods are generally very safe, as with any surgical procedure, there are some potential risks. These may include infection at the implant site, allergic reactions (though extremely rare with titanium), or mechanical complications. However, the occurrence of these issues is minimal, and the benefits typically far outweigh the potential risks.

Can medical titanium rods be removed if necessary?

Yes, medical titanium rods can be removed if required, though this is rarely necessary. Removal procedures are typically only performed in cases of infection, implant failure, or when the therapeutic goal has been achieved and the implant is no longer needed. The decision to remove an implant is made on a case-by-case basis by healthcare professionals.