Understanding Medical Titanium Rods in Modern Orthopedics

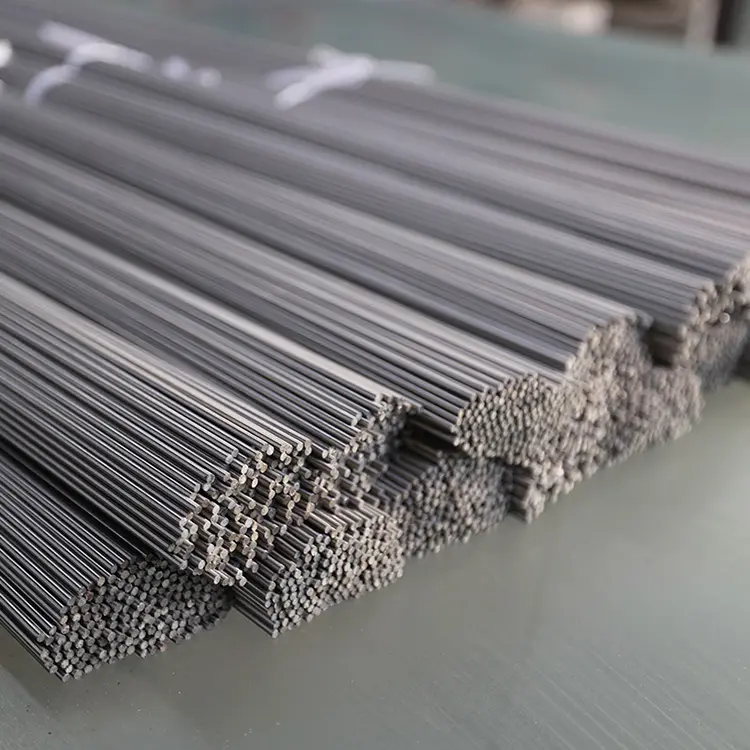

The evolution of orthopedic implants has revolutionized modern medicine, with medical titanium rods standing at the forefront of this transformation. These sophisticated medical devices have become indispensable in orthopedic surgery, offering superior strength, biocompatibility, and long-term stability for patients requiring skeletal support or reconstruction.

Surgeons and medical professionals worldwide rely on medical titanium rods to achieve optimal patient outcomes in various procedures, from spinal fusion to long bone fracture repair. The selection process requires careful consideration of multiple factors to ensure the best possible result for each unique case.

Essential Properties of Medical Grade Titanium

Mechanical Strength and Durability

Medical titanium rods exhibit exceptional mechanical properties that make them ideal for orthopedic applications. The material's high strength-to-weight ratio ensures robust support while maintaining a relatively lightweight profile. This unique combination allows for optimal load distribution and reduces stress on surrounding bone tissue.

The durability of titanium implants is particularly noteworthy, as they can withstand years of cyclic loading without significant degradation. This characteristic is crucial for long-term implant success, especially in weight-bearing applications where material failure could lead to severe complications.

Biocompatibility and Osseointegration

One of the most significant advantages of medical titanium rods is their exceptional biocompatibility. The material's ability to form a stable oxide layer prevents adverse reactions and reduces the risk of rejection. This natural passivation process creates an interface that promotes positive tissue interaction.

The surface properties of titanium facilitate osseointegration, allowing bone cells to attach and grow directly on the implant surface. This biological bonding process ensures long-term stability and reduces the risk of implant loosening, a critical factor in successful orthopedic procedures.

Technical Specifications and Standards

Material Grades and Compositions

When selecting a medical titanium rod, understanding the various available grades is crucial. The most commonly used grades include Ti-6Al-4V (Grade 5) and commercially pure titanium (Grade 2 and 4). Each grade offers specific advantages depending on the intended application and required mechanical properties.

The composition of these alloys significantly influences their performance characteristics. Ti-6Al-4V, for instance, provides enhanced strength and fatigue resistance, making it particularly suitable for high-stress applications such as spinal fusion rods and long bone fixation devices.

Surface Treatment Options

Surface modification plays a vital role in optimizing the performance of medical titanium rods. Various treatment options are available, including plasma spraying, acid-etching, and anodization. These processes can enhance osseointegration, reduce bacterial adhesion, and improve overall implant performance.

The choice of surface treatment should align with the specific requirements of the intended application. For instance, roughened surfaces may be preferred in areas where rapid bone integration is crucial, while smoother surfaces might be more suitable for temporary fixation devices.

Design Considerations for Specific Applications

Anatomical Compatibility

The success of a medical titanium rod largely depends on its anatomical compatibility. Designers must consider factors such as rod diameter, length, and curvature to ensure proper fit and function within the target anatomical site. Custom designs may be necessary for complex cases or unique patient anatomies.

Modern imaging technologies and computer-aided design tools have revolutionized the process of creating anatomically optimized implants. These advances allow for precise customization while maintaining the essential mechanical properties of the medical titanium rod.

Load Distribution and Stress Analysis

Understanding the biomechanical forces acting on the implant is crucial for proper selection. Finite element analysis and other computational tools help predict stress distribution patterns and identify potential failure points. This information guides the selection of appropriate rod specifications and design features.

The interaction between the medical titanium rod and surrounding bone tissue must be carefully considered to prevent stress shielding and maintain healthy bone remodeling. Optimal load transfer ensures long-term stability and reduces the risk of complications.

Quality Assurance and Regulatory Compliance

Manufacturing Standards

Adherence to strict manufacturing standards is essential for medical titanium rods. Facilities must maintain ISO 13485 certification and follow Good Manufacturing Practice (GMP) guidelines. These standards ensure consistency, traceability, and quality in every production batch.

Regular quality control testing, including mechanical testing, chemical analysis, and microstructural evaluation, helps maintain the high standards required for medical implants. Documentation and validation processes provide evidence of compliance with regulatory requirements.

Certification Requirements

Medical titanium rods must meet various certification requirements depending on the intended market. FDA clearance, CE marking, and other regional certifications demonstrate compliance with safety and performance standards. Understanding these requirements is crucial for successful product selection and implementation.

Manufacturers should provide comprehensive documentation, including material certificates, testing results, and regulatory approvals. This documentation supports informed decision-making and ensures compliance with healthcare facility requirements.

Frequently Asked Questions

What makes titanium ideal for orthopedic implants?

Titanium's combination of high strength, low weight, excellent biocompatibility, and corrosion resistance makes it ideal for orthopedic implants. Its ability to osseointegrate with bone tissue and maintain long-term stability contributes to successful patient outcomes.

How long do medical titanium rods typically last?

Medical titanium rods are designed to last for many years, often throughout the patient's lifetime. The actual lifespan depends on factors such as implant location, patient activity level, and overall health status. Regular monitoring ensures optimal performance and early detection of any potential issues.

Are there any alternatives to medical titanium rods?

While alternatives such as stainless steel and cobalt-chromium alloys exist, medical titanium rods remain the preferred choice for many applications due to their superior biocompatibility, strength-to-weight ratio, and proven clinical track record. The selection of alternative materials should be based on specific patient needs and surgical requirements.